Inaccurate weighing doesn’t always mean your jewelry weighing scale is the problem. In many workshops, errors come from everyday use—small habits and environmental factors that quietly affect results.

This isn’t a user manual. These are ten practical tips from real jewelry work, designed to help you get more reliable results from the jewelry weighing scale you already use.

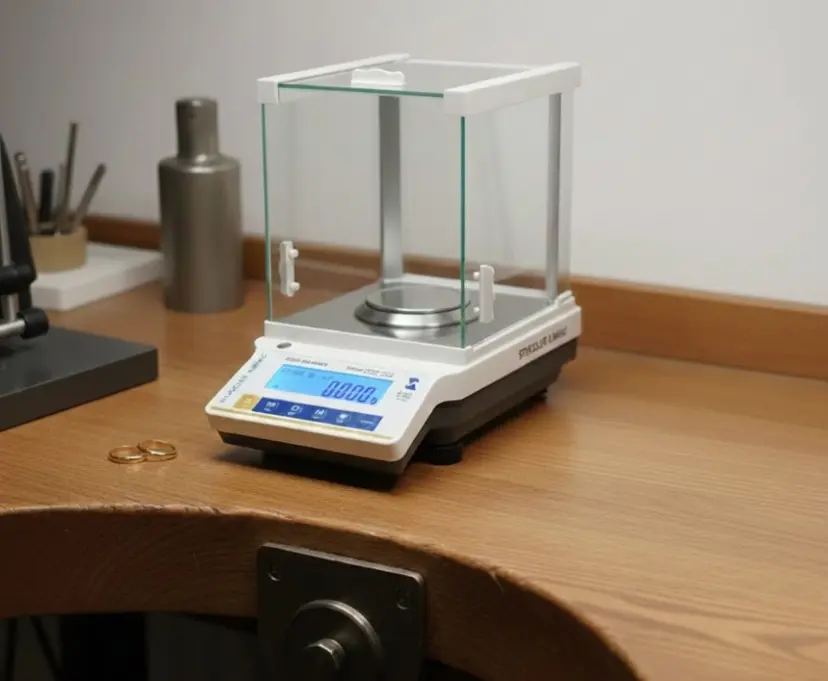

Tip 1: Always Place Your Scale on a Stable, Level Surface

A slight tilt is enough to cause invisible weighing errors.

If you have ever weighed the same ring twice and seen two different numbers, the surface is often the culprit. Jewelry weighing scales are designed to work on firm, level foundations.

Key points to keep in mind:

- A solid workbench is far more reliable than a lightweight home desktop.

- Avoid placing the scale on soft pads, leather mats, or rubber sheets, which can compress unevenly.

- If your scale has leveling feet or a bubble indicator, use them.

Stability is the foundation of consistent weighing.

Tip 2: Let the Scale Warm Up Before Precise Weighing

Turning on a digital jewelry weighing scale and weighing immediately can lead to unstable readings.

Electronic components need a short period to stabilize after powering on. This matters most when measuring precious metals or gemstones where small differences affect value.

This mistake happens most often when you are in a hurry—during customer transactions or busy production runs. Giving the scale even a minute to settle can noticeably improve repeatability.

Tip 3: Calibrate Regularly — Not Only When Something Feels “Off”

Calibration is not a troubleshooting step; it is a routine.

Over time, sensors can drift due to temperature changes, frequent use, or transportation. Waiting until results look “wrong” means the scale may already have been inaccurate for weeks.

Professional users treat calibration as a habit:

- Follow the manufacturer’s calibration procedure.

- Use certified calibration weights when possible.

- Calibrate after moving the scale or changing work environments.

This is one of the clearest differences between casual and professional use.

Tip 4: Use the Tare Function Correctly

Containers are unavoidable in jewelry work, but their weight should never be part of your measurement.

Whether you are weighing gold scraps, loose gemstones, findings, or small components, the tare function ensures only the material itself is measured.

Best practice:

- Place the empty container on the weighing platform.

- Press tare to reset the display to zero.

- Add the jewelry material.

Skipping this step is one of the most common causes of hidden weighing errors.

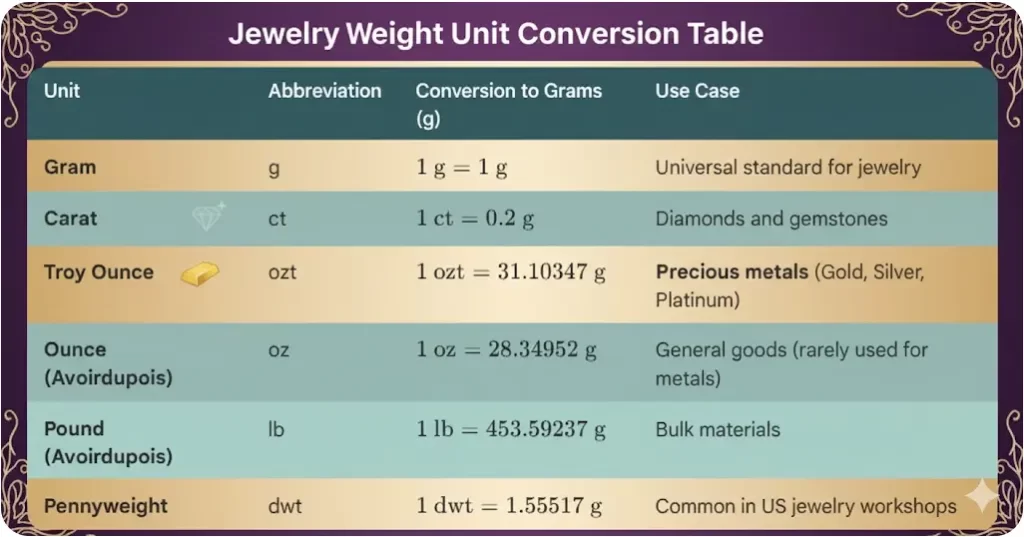

Tip 5: Choose the Right Unit for the Job (g, ct, oz)

Using the wrong unit is not just a technical issue—it affects credibility.

Jewelry weighing scales often support multiple units such as grams, carats, ounces, and troy ounces. Selecting the correct unit for each task avoids conversion mistakes and miscommunication.

For example:

- Carats (ct) for gemstones

- Grams (g) for most jewelry metals

- Troy ounces (ozt) for precious metal trading

Switching units confidently and correctly also makes your workflow appear more professional to clients.

Tip 6: Avoid Airflow and Vibrations During Weighing

Air movement and vibration are subtle but real sources of error.

Open windows, nearby fans, polishing motors, or even frequent hand movement near the scale can cause the display to fluctuate. Jewelry weighing scales are sensitive by design, especially at higher precision levels.

To reduce interference:

- Weigh in a draft-free area.

- Keep the scale away from running machinery.

- Avoid leaning on the bench while weighing.

These adjustments are simple but often overlooked.

Tip 7: Don’t Exceed the Recommended Capacity

Overloading a scale does not always cause immediate failure, but it can permanently damage the sensor.

Even if the display does not show an error, repeated overloads reduce long-term accuracy. This is especially risky when weighing heavy scrap containers or multiple items at once.

Always check:

- Maximum capacity

- Recommended working range

Staying within limits protects your investment and preserves accuracy.

Tip 8: Keep the Weighing Platform Clean

Dust, metal filings, polishing powder, and residue build up faster than most users realize.

In real jewelry workshops, these contaminants can subtly alter readings, especially when working with small weights. A clean weighing platform ensures consistent contact and stable measurements.

Make it a habit to:

- Wipe the platform with a soft, dry cloth

- Remove residue after polishing or sanding sessions

- Avoid using harsh chemicals

Cleanliness directly supports precision.

Tip 9: Handle Small Items with Tools, Not Fingers

Fingers transfer heat and natural oils.

When handling small gemstones or thin metal pieces, body temperature and skin grease can influence readings, especially on high-precision jewelry weighing scales.

Using tweezers or small tools:

- Improves measurement stability

- Prevents contamination

- Signals professional attention to detail

Clients notice these small habits, even if they do not comment on them.

Tip 10: Store Your Scale Properly When Not in Use

How you store your scale matters just as much as how you use it.

Leaving a jewelry weighing scale exposed on a busy bench invites dust, accidental impacts, and environmental stress. Over time, this contributes to drifting accuracy.

Proper storage includes:

- Turning the scale off when not in use

- Using a protective cover or case

- Keeping it away from humidity and temperature extremes

This is a simple step that protects long-term performance.

Conclusion

Accurate weighing is not about owning the most expensive jewelry weighing scale. It comes from correct usage combined with consistent habits. Small adjustments—many of which cost nothing—can significantly improve reliability, professionalism, and confidence in daily work.

As your needs grow, you may require higher precision, better stability, or commercial-grade solutions designed for continuous use. For users ready to take that next step, exploring professional jewelry weighing scale options from the Stuccler official website can help match the right tool to real-world jewelry applications.