Introduction: Precision Is Everything in Jewelry

In the jewelry world, where a fraction of a gram can make or break a deal, accurate weighing isn’t just important—it’s the backbone of your work. Whether you’re a pro appraising gemstones, a jeweler crafting delicate designs, or a hobbyist handling precious materials, your jewelry scales are only as reliable as how you use them. Even top-notch scales can give faulty readings if mishandled. Here, we uncover five common mistakes people make with jewelry scales, explain their pitfalls, and share practical tips to keep your measurements spot-on.

Mistake 1: Skipping Calibration—A Recipe for Errors

Why Calibration Matters

Calibration is like tuning a guitar before a performance—it ensures your jewelry scales hit the right notes. By checking your scale against a certified weight, you confirm its accuracy. Over time, wear, environmental shifts, or minor bumps can throw off the scale’s internal sensors, leading to skewed readings. Ignoring calibration risks costly mistakes, especially when dealing with high-value gems or metals.

Signs Your Scale Needs Calibration

Spot an uncalibrated scale before it costs you:

- Inconsistent Readings: Weigh the same item multiple times under the same conditions. Different results? Your scale’s off.

- Mismatched Known Weights: Use certified calibration weights. If the scale shows a weight far from the known value, it needs adjusting.

- Wobbly Zero Point: An empty scale should settle at zero. If the display fluctuates or drifts, calibration is overdue.

Solutions: Make Calibration a Habit

Keep your jewelry scales accurate with these steps:

- Set a Calibration Schedule: Calibrate weekly for heavy professional use or monthly for lighter hobbyist work. Check your scale’s manual for specific guidance.

- Use Certified Weights: Invest in clean, high-quality calibration weights matched to your scale’s capacity and precision.

- Follow the Manual: Each scale has a unique calibration process. Stick to the manufacturer’s instructions, typically involving a calibration mode and specific weights.

Mistake 2: Placing Scales on Uneven or Shaky Surfaces

How Unstable Surfaces Mess Up Readings

Jewelry scales measure gravity’s pull on an object, but an uneven or wobbly surface distorts this force, throwing off the sensors. Even a slight tilt can skew results, and in jewelry, where tiny weight differences matter, that’s a big deal.

The Perfect Spot for Your Scale

For spot-on readings, your scale needs:

- A Level Surface: Before weighing, confirm the surface is flat using a bubble level.

- Adjust the Feet: Many jewelry scales have adjustable feet. Tweak them until the scale is level, especially if it has a built-in bubble indicator.

Solutions: Set Up a Stable Weighing Station

- Check Levelness Every Time: Before weighing, confirm the surface is flat using a bubble level.

- Adjust the Feet: Many jewelry scales have adjustable feet. Tweak them until the scale is level, especially if it has a built-in bubble indicator.

- Create a Dedicated Space: Reserve a vibration-free, stable area in your workspace for weighing to minimize external interference.

Mistake 3: Overloading the Scale – Pushing Past the Limit

Why Overloading Hurts

Every jewelry scale has a maximum capacity set by the manufacturer.

- Skew Readings: Overloaded sensors give unreliable results.

- Damage Components: Repeated overloading can break delicate parts, leading to pricey repairs or replacement.

- Void Warranties: Damage from overloading often isn’t covered by warranties.

Know Your Scale’s Limits

Check your scale’s manual or label for its maximum capacity (in grams, carats, or ounces) and stick to it.

Solutions: Weigh Smart

- Verify Weight First: Estimate an item’s weight before placing it on the scale to ensure it’s within capacity.

- Weigh in Batches: For large quantities, split items into smaller groups and use the tare function to measure each batch accurately.

- Upgrade for Big Jobs: If you often handle heavier items, consider a higher-capacity jewelry scale from Stuccler.

Mistake 4: Misusing or Ignoring the Tare Function

Why the Tare Function Is a Game-Changer

The tare function (often a “Tare” or “Zero” button) lets you zero out the weight of containers or tools, giving you the net weight of your jewelry. Misusing or skipping it can lead to costly errors in pricing, inventory, or material calculations.

Common Tare Slip-Ups

- Skipping Tare: Weighing jewelry in a container without taring includes the container’s weight, inflating the reading.

- Taring Too Early: Taring with jewelry already on the scale resets the wrong zero point, giving false net weights.

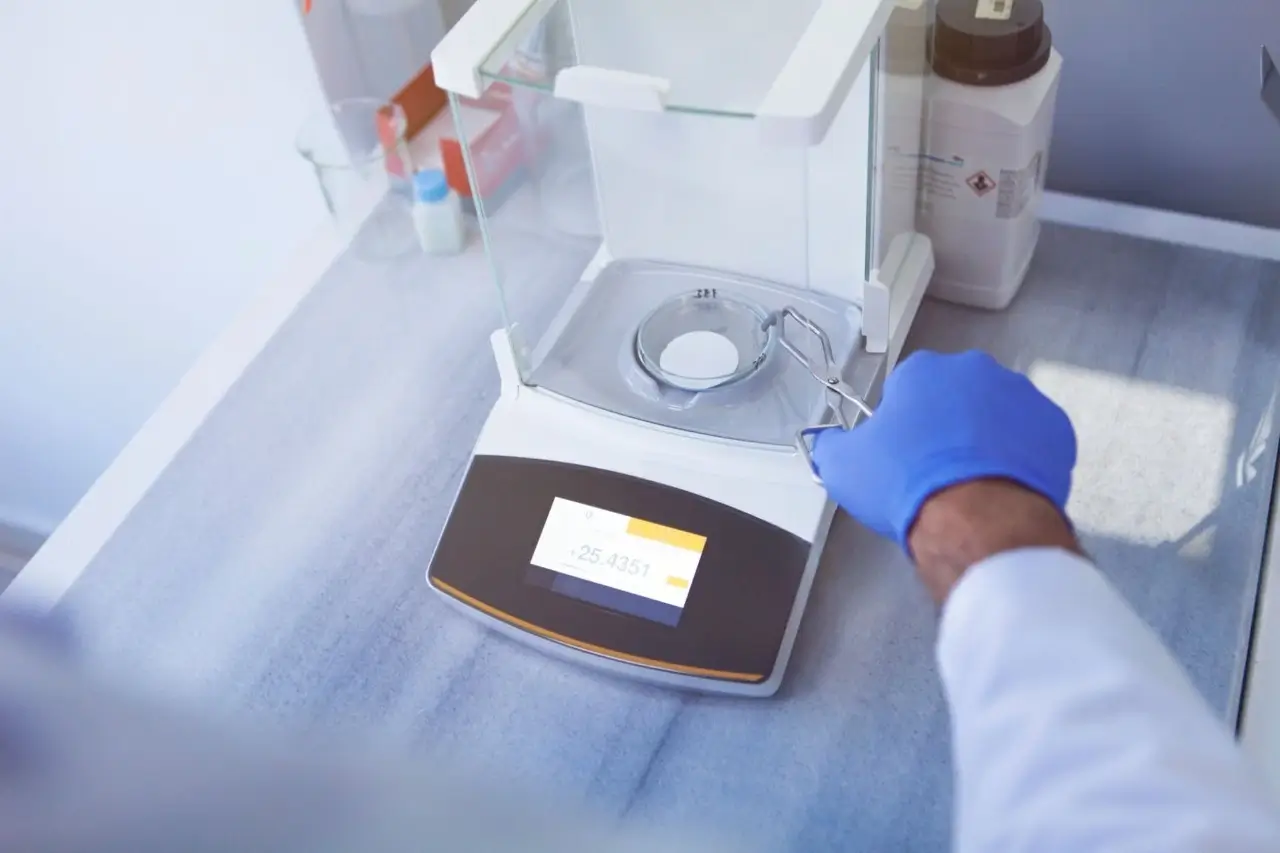

Solutions: Master the Tare Process

- Place the Empty Container: Set your container on the scale and wait for a stable reading.

- Hit Tare: Press the “Tare” or “Zero” button to reset the display to zero.

- Add Jewelry: Place your items in the container. The scale now shows only the jewelry’s weight.

Mastering the tare function ensures precise, professional measurements every time.

Mistake 5: Ignoring Environmental Factors

How Surroundings Affect Accuracy

Jewelry scales are sensitive to their environment. Small changes can throw off readings, especially for lightweight gems or metals.

- Drafts: Air from windows, fans, or AC vents can nudge the scale’s platform, causing unstable readings.

- Vibrations: Nearby machinery or a shaky table can disrupt the scale’s sensors.

- Temperature Swings: Sudden temperature changes can affect internal components. A scale moved from a cold storage area needs time to adjust.

Solutions: Control Your Weighing Environment

- Pick a Sheltered Spot: Keep your scale away from drafts, open windows, or vents.

- Use a Solid Surface: Place the scale on a sturdy, vibration-free table.

- Let It Warm Up: If the scale’s been in a cold or hot space, let it sit at room temperature for 30–60 minutes before use.

- Consider a Draft Shield: For ultra-precise tasks, use a weighing enclosure to block air currents and vibrations.

Conclusion: Weigh with Confidence

Accurate measurements are the heart of jewelry work, and avoiding these five mistakes—skipping calibration, poor placement, overloading, misusing the tare function, and ignoring environmental factors—will keep your jewelry scales performing at their best. Pair these tips with a high-quality scale from Stuccler, and you’ll ensure every weigh-in is precise, professional, and trustworthy. Check out our range of reliable jewelry scales to elevate your craft and safeguard your reputation.