There is a direct, causal relationship between the daily maintenance of your electronic balance and its measurement accuracy. Neglecting basic upkeep leads to “drift,” poor repeatability, and costly data errors. Proper maintenance is not merely about aesthetics; it is essential for protecting the internal precision sensors (load cells) from environmental stress and mechanical fatigue.

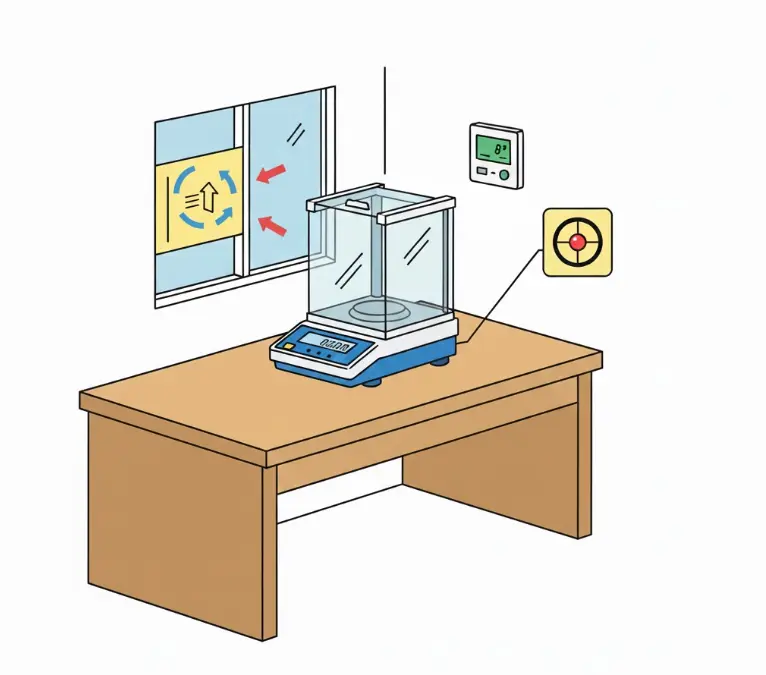

I. Optimizing the Installation Environment

Before you even turn on the device, the environment acts as the first line of defense for accuracy. Even the most expensive analytical balance will produce erratic readings if placed in a suboptimal location.

Vibration Isolation

Precision sensors can detect the slightest tremors. To ensure stability:

- Use a dedicated weighing table, ideally one made of stone or high-density material with anti-vibration mounts.

- Keep the balance away from vibration sources such as centrifuges, elevators, or heavy industrial machinery.

Airflow and Climate Control

Moving air creates “wind lift” on the weighing pan, causing the display to fluctuate.

- Avoid drafts: Stay away from air conditioner vents, open windows, and fans.

- Traffic flow: Do not place the balance in high-traffic corridors where the movement of people creates air turbulence.

- Temperature Stability: Maintain a constant ambient temperature. Direct sunlight can cause the internal components to expand or contract, leading to significant measurement drift.

Perfect Leveling

An unlevel balance introduces “corner load errors.” Always check the leveling bubble (usually located at the rear or base of the unit) before starting your work. Adjust the leveling feet until the bubble is perfectly centered.

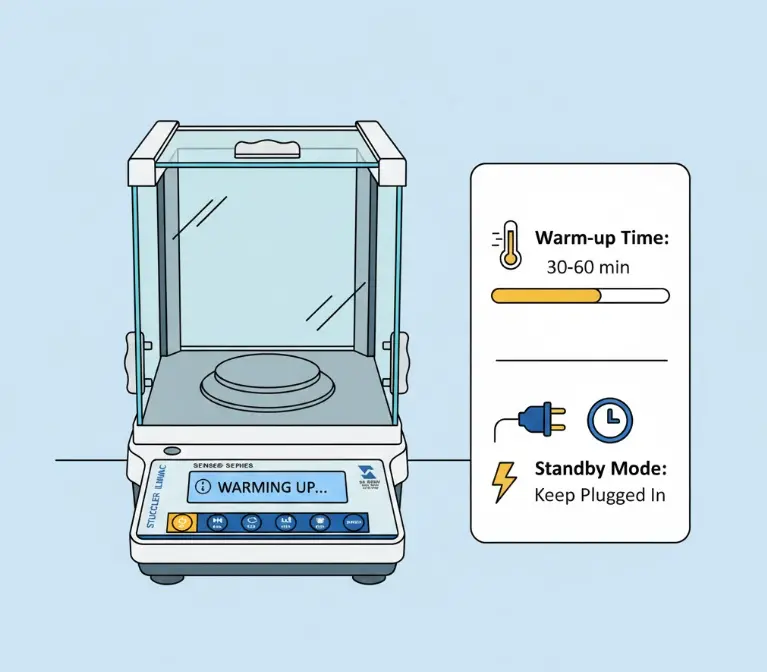

II. Correct Warm-up and Initialization

Electronic components require time to reach thermal equilibrium. If you attempt to weigh samples immediately after plugging in the device, the internal heat generated by the electronics will cause the readings to shift.

- Warm-up Times: For a standard precision balance, 30 minutes is usually sufficient. However, for a high-precision 0.0001g analytical balance, we recommend a warm-up period of 30 to 60 minutes.

- Standby Mode: For instruments in frequent use, it is best to leave the power connected. Most modern balances have a power-saving or “standby” mode that keeps the internal sensors warm without staying fully active.

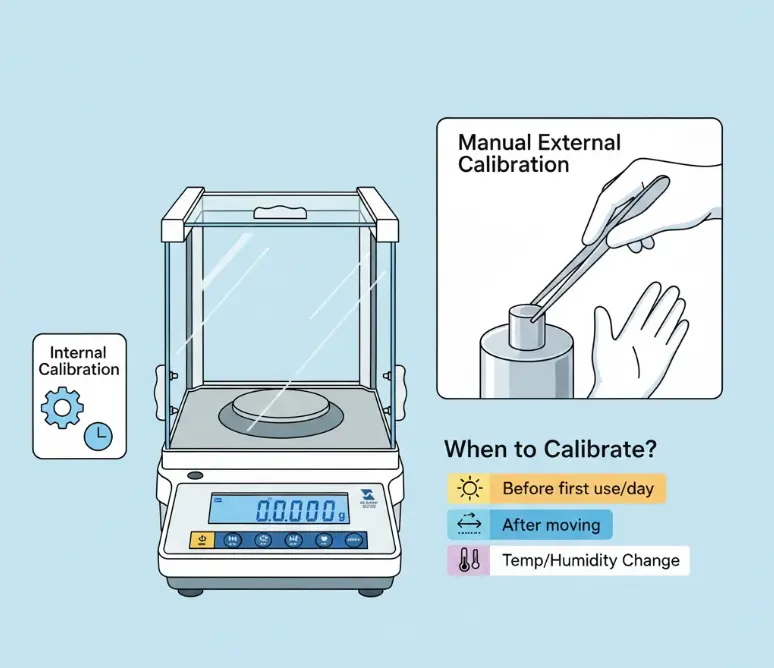

III. Calibration: The Core of Ensuring Accuracy

Calibration aligns the balance’s software with physical reality. Without regular calibration, accuracy is purely theoretical.

Internal vs. External Calibration

Many high-end electronic balances feature Internal Calibration, which uses an automated motorized weight. This is often triggered by changes in time or temperature. However, Manual External Calibration using certified weights is still necessary for periodic verification and compliance with quality standards.

Professional Weight Management

When performing external calibration, the quality of your test weights is paramount.

- Never touch weights with bare hands: Skin oils and moisture can alter the mass of a calibration weight.

- Always use dedicated tweezers or gloves provided with the weight set.

When to Calibrate?

At a minimum, calibrate your balance:

- Before the first measurement of the day.

- Whenever the balance is moved to a new location.

- After a significant change in room temperature or humidity.

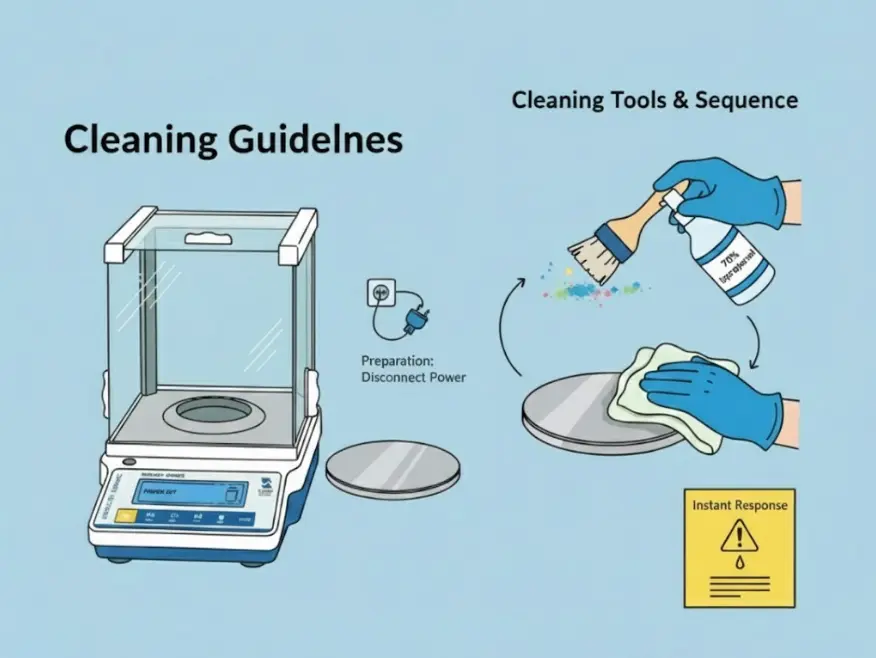

IV. Standard Cleaning Guidelines

A clean balance is a functional balance. Corrosive chemicals or stray powders can migrate into the housing and damage the load cell.

- Preparation: Always disconnect the power before deep cleaning.

- Tools: Use a soft hair brush for dry powders and a lint-free cloth for surfaces. A mild, neutral cleaning agent (like a 70% isopropyl alcohol solution) is generally safe for stainless steel pans.

- Sequence: Remove the weighing pan first. Clean the surrounding area from the inside out, ensuring that no debris falls into the hole where the pan support sits.

- Instant Response: If a chemical spill occurs, deal with it immediately. Acids and bases can quickly corrode the sensitive metal components of the weighing mechanism.

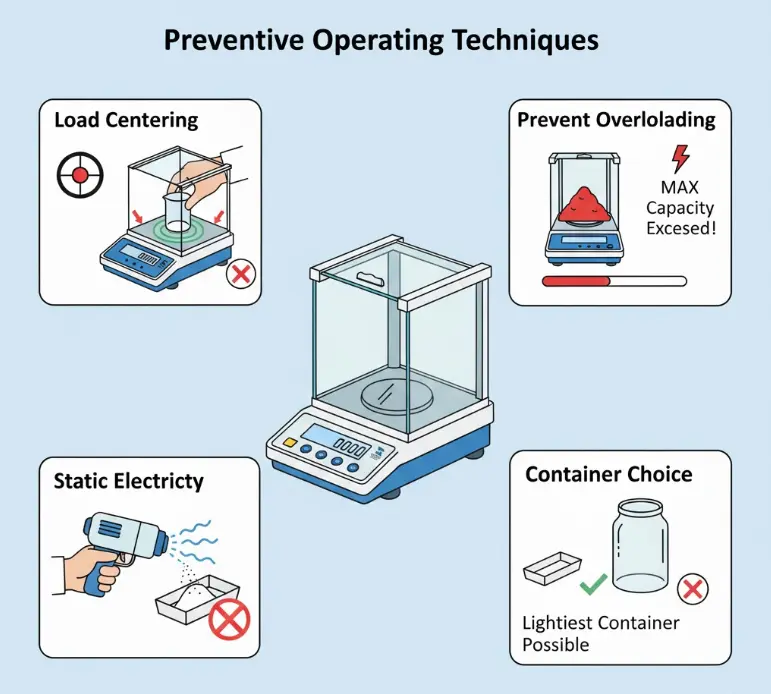

V. Preventive Operating Techniques

How you interact with the balance during the weighing process determines the longevity of the sensor.

- Load Centering: Always place your sample in the center of the pan. Off-center loading puts uneven stress on the sensor and increases the margin of error.

- Prevent Overloading: Every balance has a maximum capacity. Never exceed this limit, even momentarily, as it can permanently deform the internal weighing mechanism.

- Static Electricity: In dry environments, powders can become electrostatically charged, causing them to “jump” or produce unstable readings. Using an anti-static ionizer or “static-free” weighing boats can solve this issue.

- Container Choice: Use the lightest container possible for your sample to maximize the available weighing range.

Conclusion

Maintaining an electronic balance is a commitment to data integrity. A small, consistent investment in daily maintenance—keeping it level, calibrated, and clean—results in a long-term output of reliable, reproducible data. By following these professional protocols, you protect your equipment and your research.

If you are looking to upgrade your laboratory capabilities with high-precision instruments, explore the full range of professional weighing solutions at the Stuccler official website, where accuracy meets durability.