Electronic balances are long-term lab assets, yet 80% of buyers regret their choice due to poor planning. Buying wrong is expensive. Avoiding these mistakes ensures data reliability, compliance, and lower costs for the next decade. As a weighing expert, I’ll show you how to avoid these common traps.

I. 7 Mistakes to Avoid When Buying an Electronic Balance

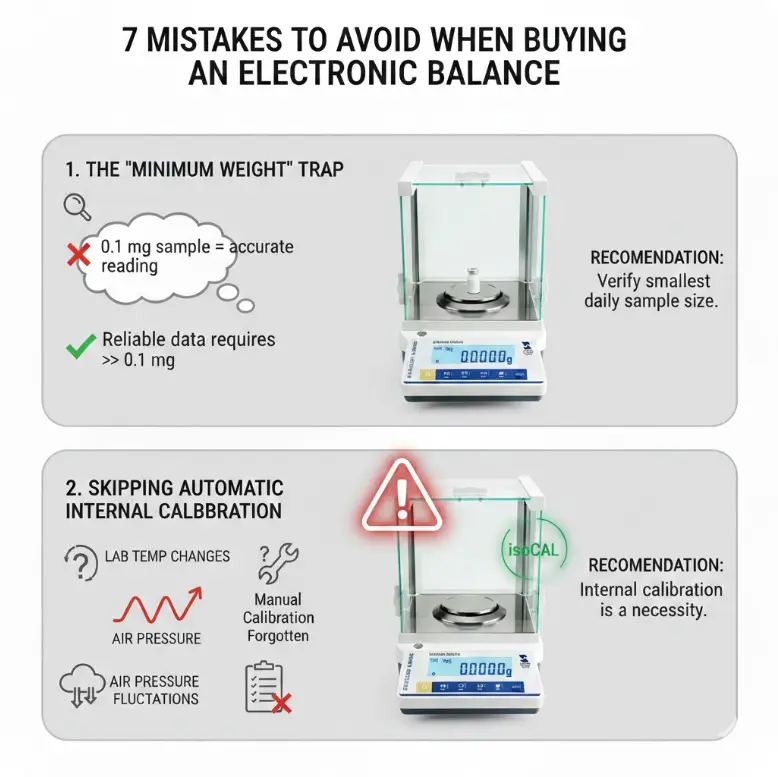

1. The “Minimum Weight” Trap

Many buyers assume a balance with a readability of 0.1 mg can accurately weigh a 0.1 mg sample. This is a critical error.

Readability is simply the smallest increment the screen can display. It is not the same as accuracy. According to USP (United States Pharmacopeia) standards, you must account for a safety factor. To get reliable data, your minimum weighing value usually needs to be dozens of times larger than the readability.

Recommendation: Always verify your smallest daily sample size before you click “buy.”

2. Skipping Automatic Internal Calibration

It is tempting to save thousands by choosing a manual calibration model. You might think, “I can just use external weights.”

In reality, laboratory temperature changes and air pressure fluctuations cause reading drift. If you skip isoCAL (fully automatic triggered calibration), you risk human error. Manual calibration is often forgotten, leading to potential data falsification during audits.

Recommendation: If your lab temperature varies even slightly, internal calibration is a necessity, not an option.

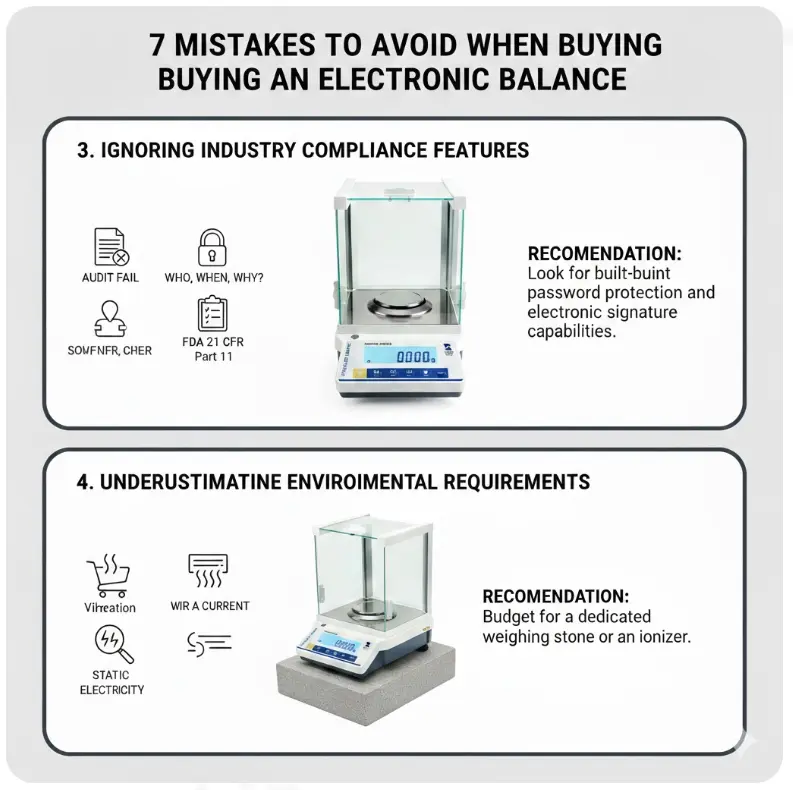

3. Ignoring Industry Compliance Features

Imagine buying a sleek new balance, only to fail an audit. This happens when buyers overlook audit trail requirements.

In the pharmaceutical and food sectors, FDA 21 CFR Part 11 compliance is non-negotiable. If your balance cannot track “who, when, and why” a weight was recorded, the entire unit becomes a liability.

Recommendation: Look for built-in password protection and electronic signature capabilities.

4. Underestimating Environmental Requirements

High-precision balances are sensitive. A balance with 0.0001g precision can be affected by the vibration of a passing cart or a nearby air vent.

Without a vibration isolation table or an anti-static device, you are buying a “bouncing random number generator.” Static electricity is a silent killer of accuracy, especially when weighing powders in dry environments.

Recommendation: Budget for a dedicated weighing stone or an ionizer if you need high precision.

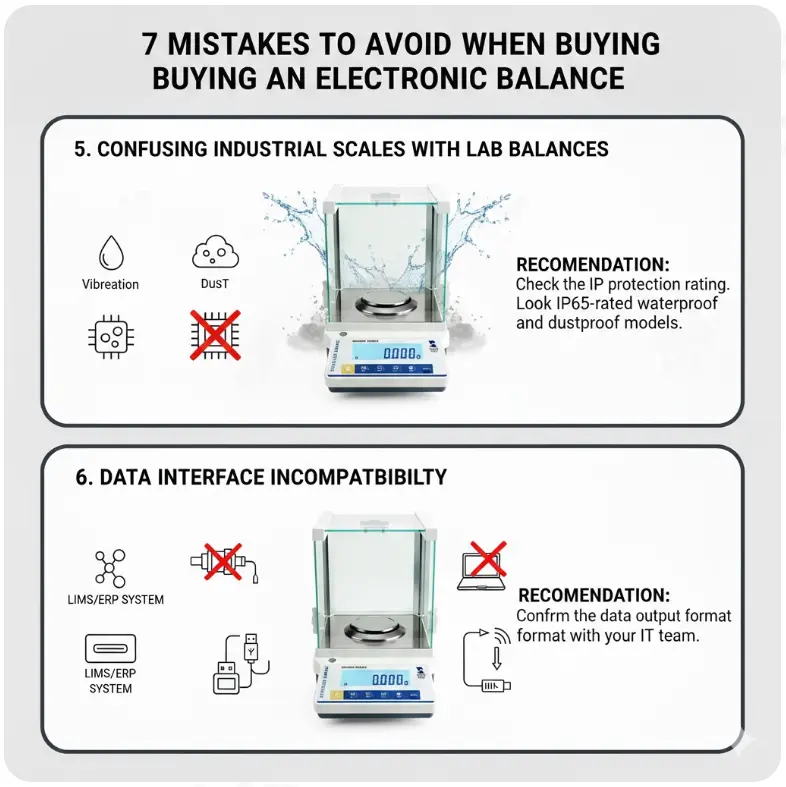

5. Confusing Industrial Scales with Lab Balances

Using a standard laboratory balance in a dusty or humid warehouse is a recipe for disaster.

Sensors in lab balances are delicate. They are not built for splashes or heavy dust. One spilled chemical can cause a short circuit or permanent corrosion.

Recommendation: Check the IP protection rating. For harsh areas, look for IP65-rated waterproof and dustproof models.

6. Data Interface Incompatibility

Never assume a USB port means “plug and play” with your LIMS or ERP system.

Many older models rely on RS232 ports. These require expensive converters that often fail or lose data. If your IT architecture is modern, a balance without Ethernet or Wi-Fi will be a bottleneck.

Recommendation: Confirm the data output format with your IT team before finalizing the purchase.

7. Choosing “Orphan Brands” or Unauthorized Channels

The cheapest price on a comparison site is often a trap.

Precision instruments require IQ/OQ/PQ validation. Unauthorized vendors cannot send original manufacturer engineers for on-site service. If the balance breaks, you might wait months for parts.

Recommendation: Always ask for an authorization certificate. Local after-sales support is worth the extra initial cost.

II. Specific Pitfall Avoidance Guide for Different Industries

A. Pharmaceutical and Biotechnology

Compliance is your north star. Do not buy a basic model.

- The Danger: Failing an inspection due to lack of an Audit Trail.

- The Fix: Prioritize models with multi-level user management. It must record every change made to the settings.

B. Chemical & Materials Science

Durability is your priority. Chemicals are aggressive.

- The Danger: Sensancy failure within six months due to corrosion.

- The Fix: Ensure the weighing pan is 316L stainless steel. If working with volatiles, ensure the unit has Ex certification for explosion-proof safety.

C. Industrial Manufacturing & Automotive

Efficiency and speed matter most here.

- The Danger: Constant “hunting” for a stable reading due to floor vibrations.

- The Fix: Choose an industrial balance with Digital Filter Settings. You need a “Settling Time” of less than 1 second to keep the line moving.

D. Jewelry & Precious Metals

Legal metrology is the key.

- The Danger: Fines for using uncertified equipment in trade.

- The Fix: Look for NTEP or OIML markings. The spec sheet must say “Legal for Trade.”

Summary

Buying an electronic balance is an investment in your data’s integrity. Don’t just look at the price tag. Focus on the minimum weight, internal calibration, and your specific industry’s compliance needs. Avoid unauthorized sellers and ensure your environment is ready for high precision.

Ready to find a balance that actually fits your workflow? At Stuccler, we specialize in precision weighing solutions that meet global standards. Explore our range of professional Electronic Balances today and ensure your laboratory or production line is built on accuracy.