In the modern lab, choosing a balance is a strategic choice between precision, speed, and cost. While analytical models handle micro-grams, top loading balances offer the versatility needed for high-volume, heavy-duty weighing. This guide helps you navigate core specs and environmental factors to find the ideal “sweet spot” for your specific operational and compliance needs.

I. Why Choose a Top Loading Balance?

Why do most labs reach for a top loader first? It comes down to three main factors:

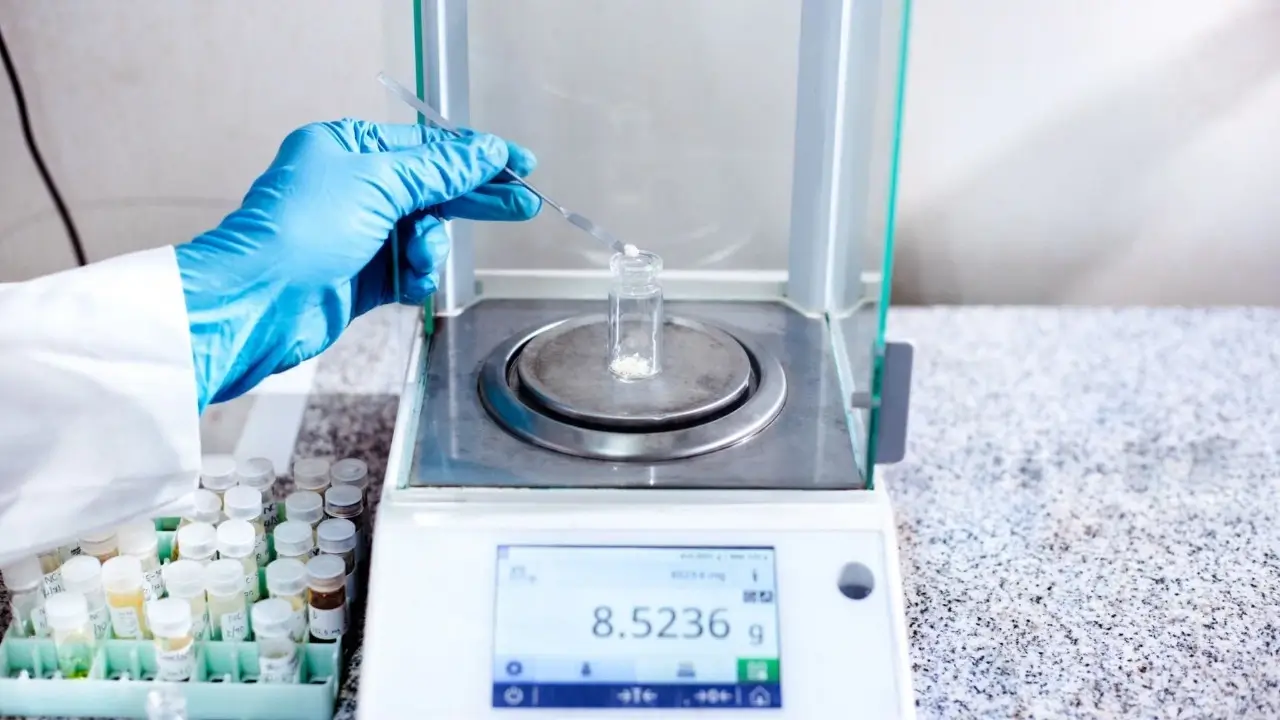

- Operational Flexibility: Unlike analytical balances encased in glass, these units offer an open weighing pan. This makes it easy to use large beakers, oddly shaped containers, or bulky industrial samples.

- Fast Stabilization: Time is money. Top loaders settle on a final reading in seconds. This significantly boosts efficiency during high-frequency weighing tasks.

- Massive Weighing Range: These tools are versatile. They can handle loads from a few grams up to tens of kilograms. One machine can often serve multiple departments.

II. Understanding the Key Specifications of Top-Loading Balances

Before you buy, you must understand the “DNA” of the balance. Don’t let the jargon confuse you.

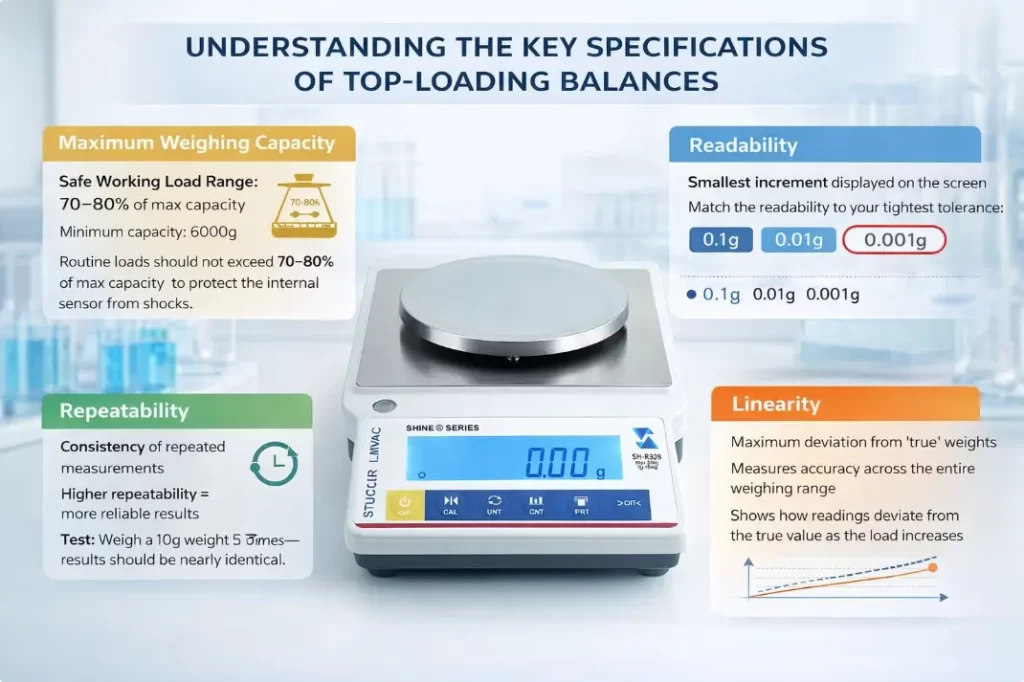

Maximum Weighing Capacity

This is the limit. However, never run your balance at 100% capacity. We recommend a “safety buffer.” Choose a model where your heaviest sample plus container weighs no more than 120% of the rated capacity. This protects the sensitive internal load cell from accidental shocks.

Readability

This tells you the smallest increment the balance can display. Common increments include 0.1g, 0.01g, and 0.001g. Always match this to your tightest tolerance requirements.

Repeatability

This is the most critical quality measure. If you weigh the same 10g weight five times, do you get the same result every time? Higher repeatability means more reliable data and fewer re-tests.

Linearity

Linearity is about accuracy across the entire range. It measures the maximum deviation from the “true” weight as you move from zero to the maximum capacity.

III. The Indispensable Working Environment for Top-Loading Balances

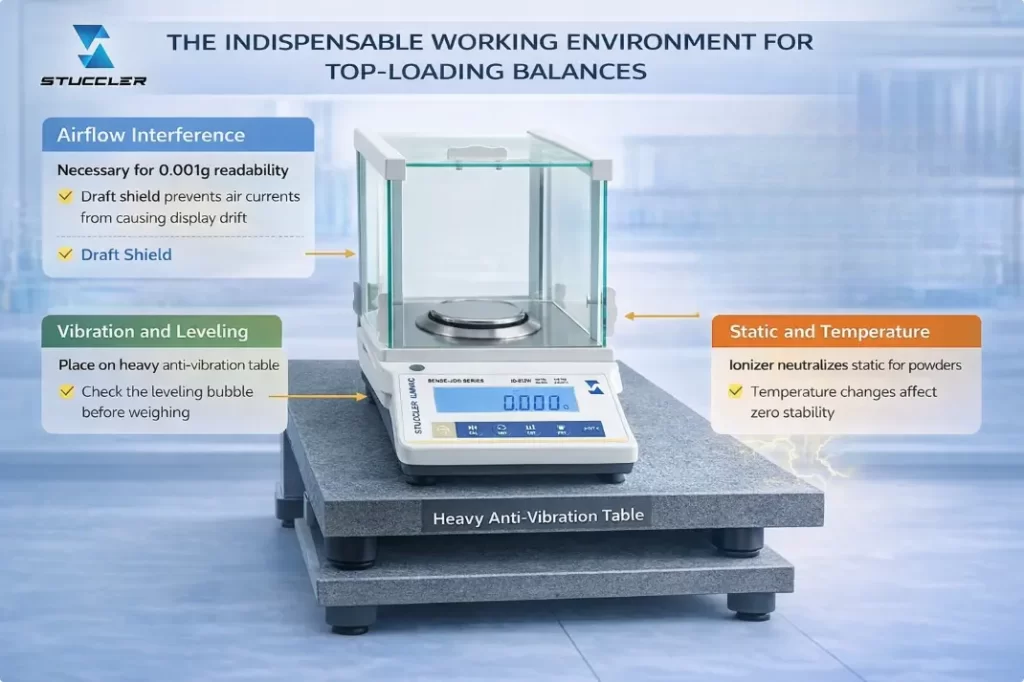

A balance is only as good as the table it sits on. External variables can turn a high-end tool into a source of frustration.

- Airflow Interference: If you use a 1mg (0.001g) balance, air currents are your enemy. These models must be equipped with a draft shield to prevent the numbers from “drifting.”

- Vibration and Leveling: Even footsteps can affect precision. Use a heavy anti-vibration table. Always check the leveling bubble before starting. A tilted balance is an inaccurate balance.

- Static and Temperature: Dry air leads to static electricity, especially with powders. This causes samples to “jump” or readings to fluctuate. Furthermore, ambient temperature changes can cause internal components to expand or contract, shifting your zero point.

IV. Advanced Features of Top-Loading Balances

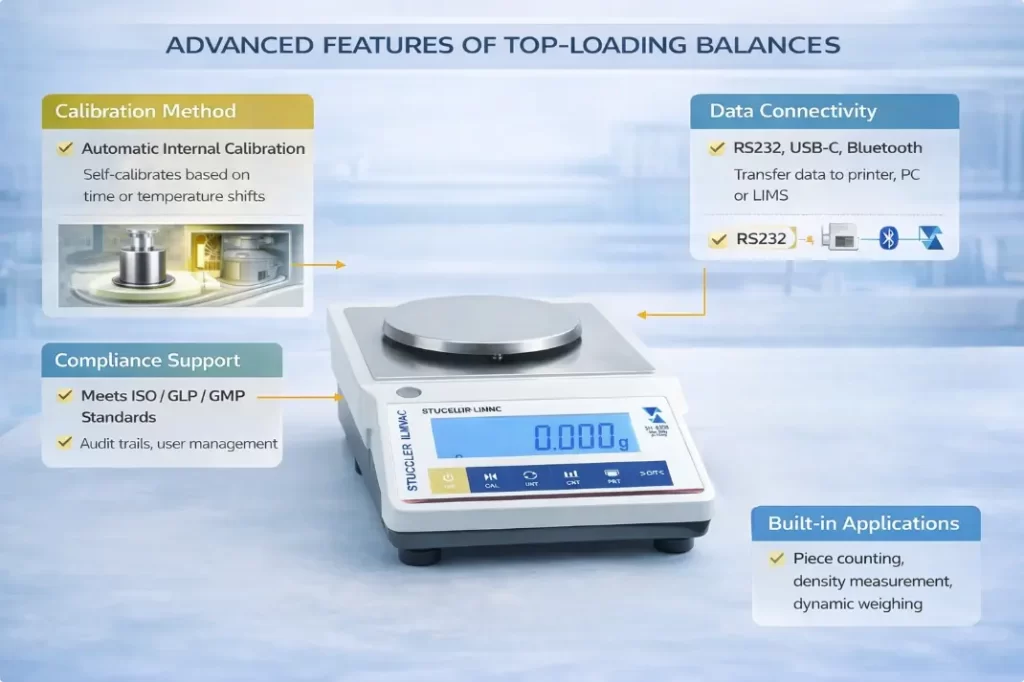

Modern top loading balances offer more than just a weight reading. They are data management hubs.

- Calibration Method: Do you want to manually place weights every morning? If not, choose Automatic Internal Calibration. The balance uses internal motors to calibrate itself based on time or temperature shifts.

- Data Connectivity: Efficiency requires integration. Look for RS232, USB-C, or even Bluetooth. This allows you to send data directly to a printer or a Laboratory Information Management System (LIMS).

- Compliance Support: For pharmaceutical or regulated industries, ensure the device supports ISO/GLP/GMP formats. Features like audit trails and user hierarchy management are essential for accountability.

- Built-in Applications: Many models include software for piece counting, density measurement, or dynamic weighing (for moving animals).

V. Scenario Matching: Find Your Perfect Fit

| Requirement Level | Application Examples | Recommended Accuracy | Essential Features |

| Precision Level | Pharmaceutical R&D | 0.001g | Internal calibration, Draft shield |

| Standard Level | Food Quality QC | 0.01g | USB interface, Vibration filtering |

| Practical Level | Warehouse, Education | 0.1g / 1g | Reinforced casing, High capacity |

VI. Final Check: The 2-Minute Self-Test

Before you hit “order,” answer these three questions:

- Does my room have temperature swings? If yes, buy a model with internal calibration.

- Are my samples powders? If yes, you likely need an ionizer to neutralize static.

- Do I need to save data? Check for a USB-C port to avoid manual logging errors.

Summary

The ideal balance is a tool that disappears into your workflow. It should adapt to your environment and meet your accuracy needs without unnecessary complexity.

Reliability shouldn’t be a luxury. At Stuccler, we bridge the gap between high-end performance and practical laboratory budgets. Browse our latest Top Loading Balance inventory now to find a model that stands up to your toughest weighing challenges. And speak with our experts to find your ideal match.