Why the Right High-Precision Balance is Crucial

In scientific research, quality control, and specialized industries, precision is essential. The right high-precision balance is crucial because it prevents distorted results, material waste, and financial loss. Choosing the correct instrument is the fundamental step toward ensuring consistent, accurate, and trustworthy outcomes.

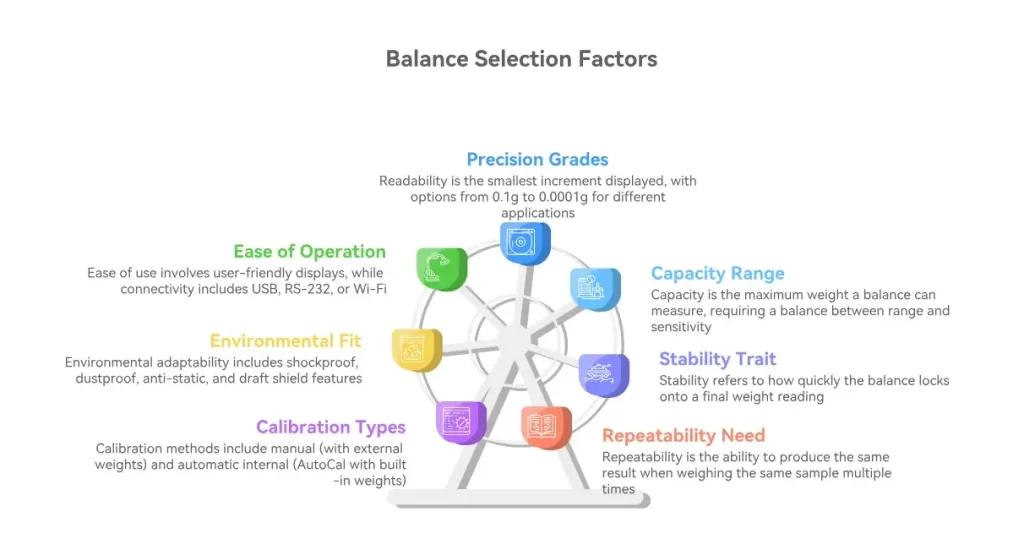

Key Factors to Consider When Choosing

Choosing the right balance means matching your needs to the instrument’s capabilities.

Readability & Precision

The most important factor is readability—the smallest increment displayed.

- 0.1g or 0.01g: Suitable for many industrial or non-critical applications.

- 0.001g (Milligram Precision): Ideal for jewelry, chemical preparation, and educational labs.

- 0.0001g (Analytical Precision): Required for pharmaceutical research, advanced chemistry, and demanding lab work.

Capacity (Weighing Range)

Capacity is the maximum weight a balance can measure. Higher capacity can reduce sensitivity, so balance is key. Select a capacity that comfortably covers your largest samples without overspending on unnecessary range.

Stability & Repeatability

- Stability: How quickly the balance locks onto a final reading.

- Repeatability: The ability to produce the same result when weighing the same sample multiple times. For scientific or quality control work, repeatability is non-negotiable.

Calibration Method

Calibration ensures accuracy over time.

- Manual Calibration: Requires external test weights and operator input.

- Automatic Internal Calibration (AutoCal): Uses built-in weights to adjust automatically for temperature changes or schedules. Highly recommended for precision-critical environments.

Environmental Adaptability

Your work environment can affect accuracy. Look for features like shockproof housing, dustproof seals, anti-static coatings, and draft shields to minimize errors.

Ease of Use & Connectivity

User-friendly displays (often touchscreen) streamline workflows. Connectivity options such as USB, RS-232, or Wi-Fi make data transfer and compliance reporting much easier.

Choosing by Application Scenario

Different industries require different specifications:

- Jewelry and Gemstones: Focus on speed and milligram precision (0.001 g or better). Draft shields are particularly valuable.

- Laboratories and Research: Prioritize repeatability, stability, and analytical precision (0.0001 g). Automatic calibration and data logging are critical for compliance.

- Industrial and Quality Control: Focus on durability, capacity, and performance consistency. Readability requirements vary from 0.01 g to 0.0001 g depending on the material. Look for overload protection and fast data transfer.

Common Challenges and Practical Solutions

Proper Balance Setup and Placement

- Solution: Always place the balance on a stable, anti-vibration table, away from air vents and doors. Use the protective draft shield and, in dry climates, consider an anti-static bar.

Calibration Drift

All balances can drift over time, affecting measurement accuracy.

- Environmental Factors: Wind, static electricity, and temperature changes can cause errors.

Solution: Place balances on anti-vibration tables, away from doors and vents. Use draft shields and anti-static devices when needed. - Calibration Drift: Accuracy drifts naturally over time.

Solution: Schedule regular calibration. For critical work, invest in self-calibrating models. - Budget Constraints: High-precision balances are an investment.

Solution: Focus on minimum accuracy needs. A balance with strong repeatability and AutoCal may deliver better long-term value than an ultra-sensitive model lacking support features. Always consider calibration costs in your budget.

Maintenance and Best Practices

To extend the life and reliability of your balance:

- Placement: Keep the balance on a stable, level surface, away from vibrations, sunlight, and drafts.

- Calibration and Cleaning: Follow the manufacturer’s calibration schedule. Clean gently with a soft cloth and approved cleaning solutions.

- Powering On/Off: Allow 30 minutes of warm-up before critical measurements. Always follow the manufacturer’s shutdown instructions, especially for AutoCal models.

Conclusion: Making the Right High-Precision Choice

A high-precision balance influences the accuracy, efficiency, and credibility of your work for years to come. The best choice depends on your specific application, required accuracy, and operating environment.

While upfront cost matters, features like automatic internal calibration, proven repeatability, and durable construction often save money and prevent costly errors in the long run.

Invest wisely in a laboratory or analytical balance—such as those from Stuccler—to ensure that your results are consistently reliable and meet the highest standards of quality.