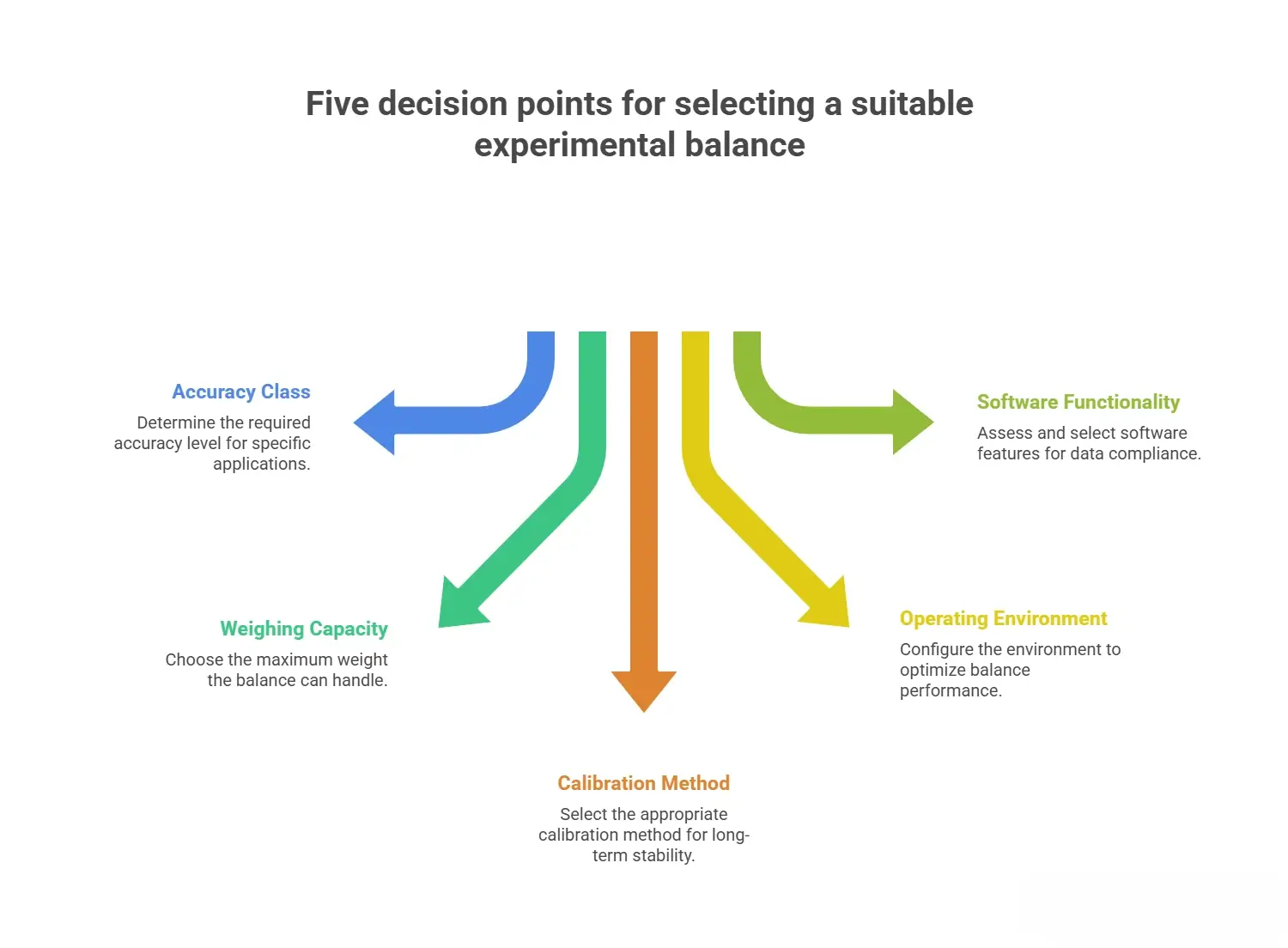

Struggling to select the right laboratory balance? This expert guide cuts through the complexity with 5 core decision points to optimize accuracy and efficiency—not just manage budget—helping you find the perfect weighing instrument for your experimental needs.

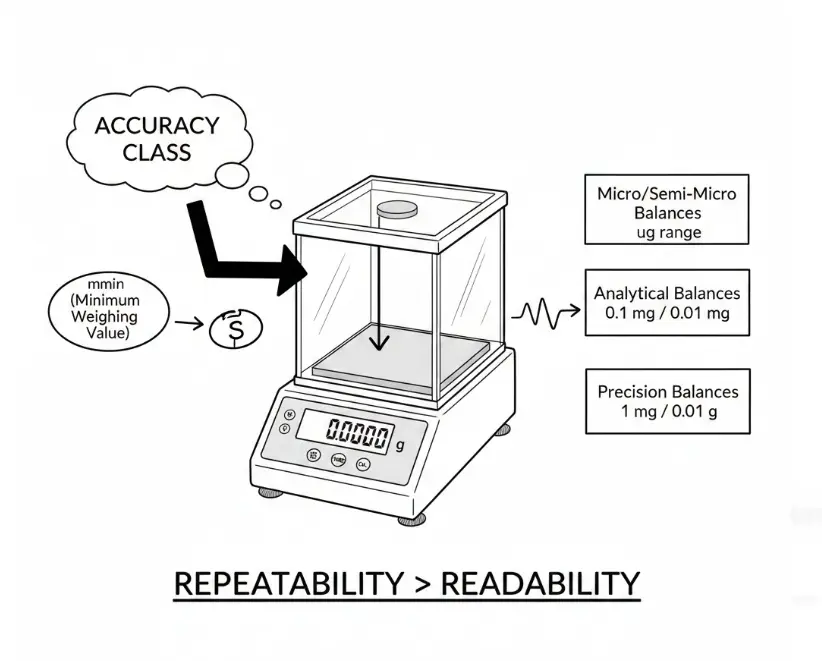

1. How to Determine the Balance’s Accuracy Class

The most critical step in selecting a precision balance is understanding that its true accuracy is determined by the minimum weighing value (mmin), not just the technical readability (d).

- Decision Basis: Accuracy is determined by mmin, the smallest weight the balance can measure reliably within your required tolerance.

- Calculation Method: First, determine the maximum permissible weighing error required for your experiment (e.g., 0.1%). You must calculate mmin using the balance’s repeatability (standard deviation σ).

- Selection Guidelines: Ensure the smallest sample weight you plan to weigh is greater than the mmin of your chosen analytical balance or precision balance. By working backward from your mmin, you determine the necessary accuracy class:

- Micro/Semi-Micro Balances: For ultra-low mmin (e.g., in μg range).

- Analytical Balances: For 0.1mg or 0.01mg readability, suitable for standard quantitative analysis.

- Precision Balances: For 1mg or 0.01g readability, suitable for larger or faster weighings.

- Key Metric: Focus more on repeatability than d. A laboratory weighing instrument with poor repeatability is inherently unreliable for scientific work.

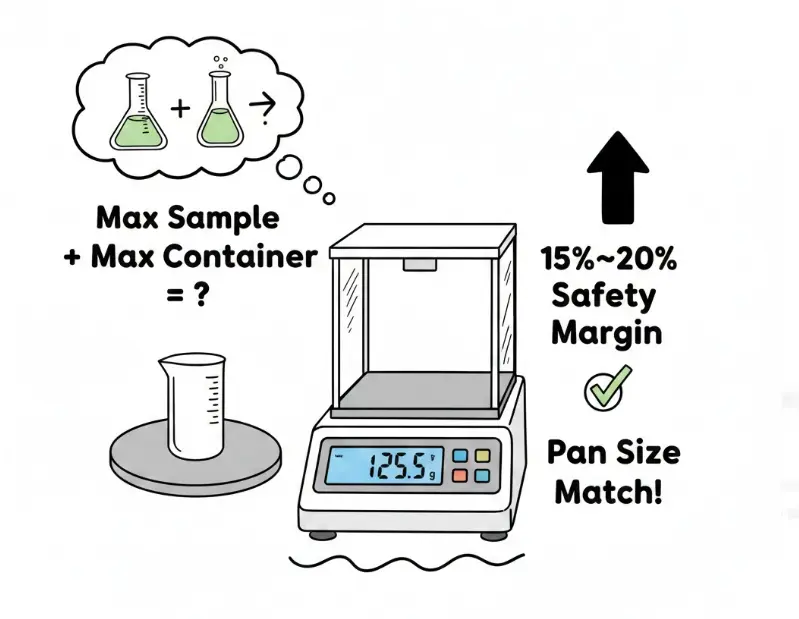

2. How to Choose Maximum Weighing Capacity

Selecting the right measuring range is essential for both functionality and longevity of the weighing scale.

- Calculate Total Load: Add the maximum sample weight you need to weigh to the weight of the heaviest container you might use (beakers, flasks, etc.) to determine your actual maximum weighing capacity.

- Safety Margin Strategy: Choose a model with a weighing range 15%~20% higher than your calculated result. This avoids operating the digital scale near full load, ensuring it operates in the middle of its range (where performance is usually most stable and precise).

- Container Matching: While determining the weighing capacity, check that the weighing pan size is large enough to accommodate your largest commonly used containers without interference from the windproof cover (if applicable).

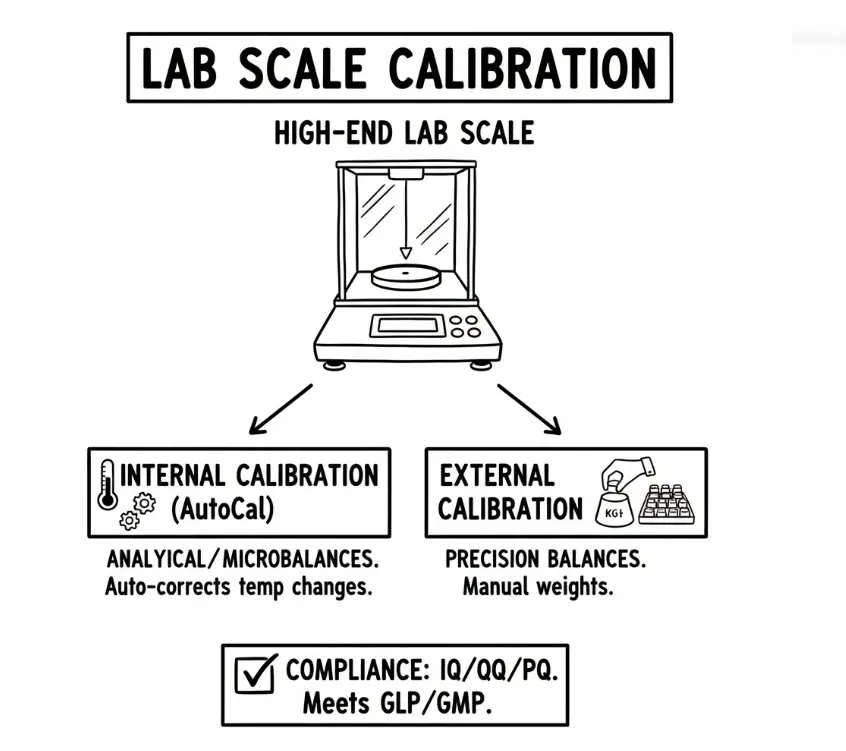

3. How to Choose a Calibration Method and Ensure Long-Term Stability

Calibration is the cornerstone of maintaining accuracy over time, especially for high-end lab scales.

- Choose Internal Calibration (AutoCal): Recommended for analytical balances and microbalances, particularly in laboratories with significant environmental temperature fluctuations. Internal calibration automatically senses changes and corrects the device, maximizing long-term accuracy and saving manual calibration time.

- Choose External Calibration: Suitable for budget-sensitive precision balances. Users must provide their own certified calibration weights and perform manual calibration periodically.

- Compliance Requirements: Confirm that the weighing equipment supports IQ/OQ/PQ (Installation, Operation, Performance Validation) procedures. This is crucial for meeting GLP/GMP regulations.

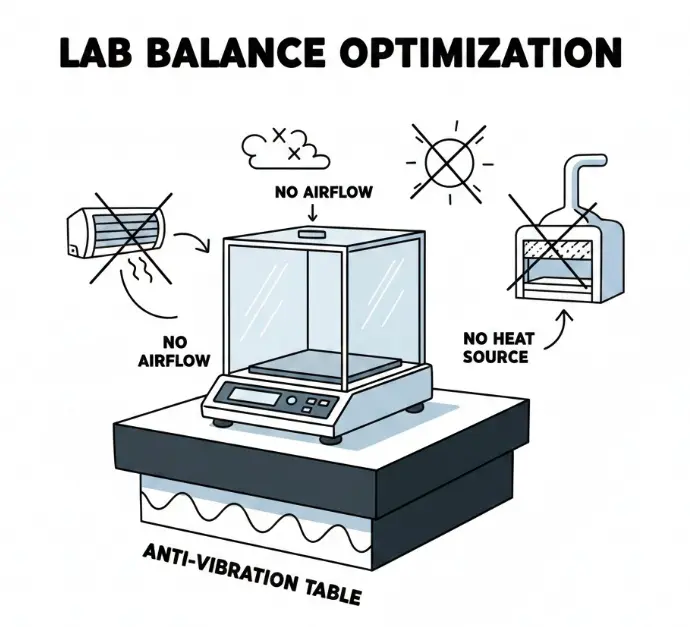

4. How to Configure and Optimize the Balance’s Operating Environment

Even the most accurate analytical balance will yield unreliable results if placed in a poor environment.

- Addressing Vibration Issues: For high-precision balances, you must invest in dedicated vibration damping tables/weighing platforms. This is a fundamental condition for ensuring mmin reliability.

- Airflow Isolation: All scientific scales with an accuracy of 0.1mg or higher must be kept away from air conditioning vents, fume hoods, and heat sources, and a windproof cover must be used at all times to isolate even the slightest air movement.

- Harsh Environment Handling: In industrial, wash-down, or humid environments, choose a rugged top-loading balance model with a high IP protection rating (dustproof and waterproof) to prevent corrosion and damage to the internal load cell.

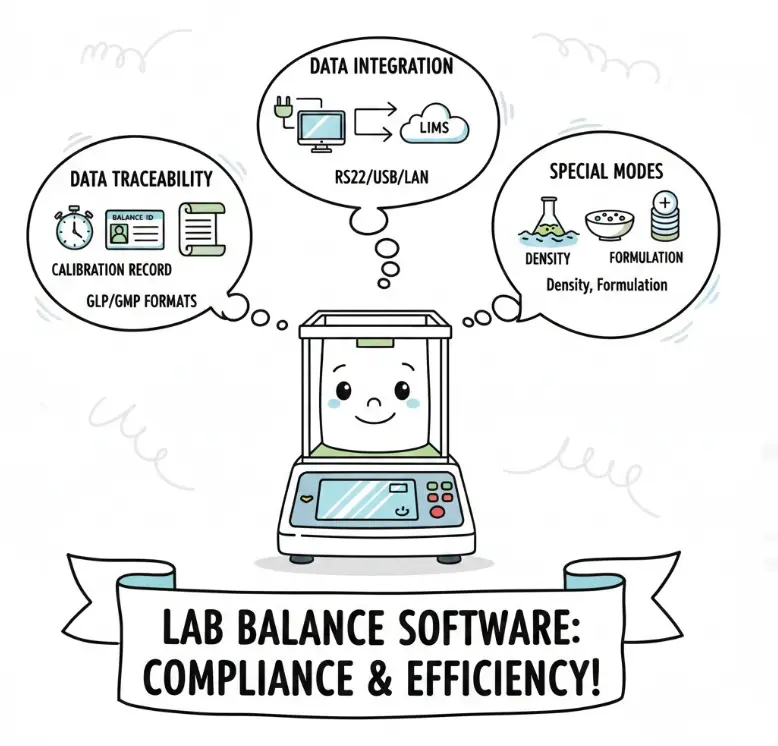

5. How to Assess and Select Software Functionality and Data Compliance

Modern laboratory balances are sophisticated data tools; their software features are essential for compliance and efficiency.

- Data Traceability: Confirm whether GLP/GMP data output formats are available. This is a mandatory requirement for data traceability in regulated industries (pharmaceuticals, etc.), ensuring every measurement includes timestamps, balance IDs, and calibration records.

- Data Integration Needs: Determine if an RS232, USB, or LAN interface is needed to directly transmit weighing results to a LIMS system or computer. Direct data transfer avoids manual transcription errors and speeds up reporting.

- Specialized Application Modes: Do you have special needs? If you require frequent density measurements, formulation weighings (multi-component), or summation weighings, choosing a model with built-in applications can significantly improve operational efficiency compared to manual calculation.

Conclusion

Choosing the right laboratory balance is a calculated decision that protects the integrity of your research or product quality.

Before final procurement, request the supplier to provide a performance test report for the balance and, if possible, conduct trials or performance verification in your laboratory environment to confirm its stability.

| Final Checklist | Requirement Status |

|---|---|

| Requirements are clearly defined and the selected balance meets them. | □ Confirmed |

| The measuring range includes a 15% safety margin. | □ Confirmed |

| Calibration method (internal/external) has been determined based on accuracy requirements. | □ Confirmed |

| Operating environment (shockproof/windproof) has been optimized. | □ Confirmed |

| Data compliance features such as GLP/GMP are available (if required). | □ Confirmed |

With these factors in mind, you’re ready to make a confident purchase. We invite you to explore the full range of high-performance Stuccler laboratory balances on our website. Our selection includes everything from robust precision balances to state-of-the-art analytical scales designed to meet the strictest mmin requirements of modern science. Find the perfect weighing solution for your lab today!

Want to learn more? After selecting your product, click to delve deeper into technical details and maintenance tips: A Comprehensive Guide to Choosing the Right Laboratory Balance