In every laboratory, manufacturing plant, or quality control department, precision defines the credibility of your work. Among all measurement instruments, the analytical balance plays one of the most crucial roles.

When measurements reach the milligram or microgram level, even the smallest error can compromise results, waste expensive materials, or cause regulatory non-compliance. That’s why selecting the right balance isn’t simply a purchasing decision—it’s an investment in reliability and accuracy.

A poorly chosen or uncalibrated analytical balance can create inconsistent data, lead to GLP/GMP violations, or increase costs through product loss and rework. This guide provides practical, experience-based advice to help you make the right choice and maintain trustworthy measurements.

I. Basics: Understanding Analytical Balances

Before exploring different models, it’s helpful to understand what defines an analytical balance and the technical indicators that determine its performance.

1.1 Definition and Classification

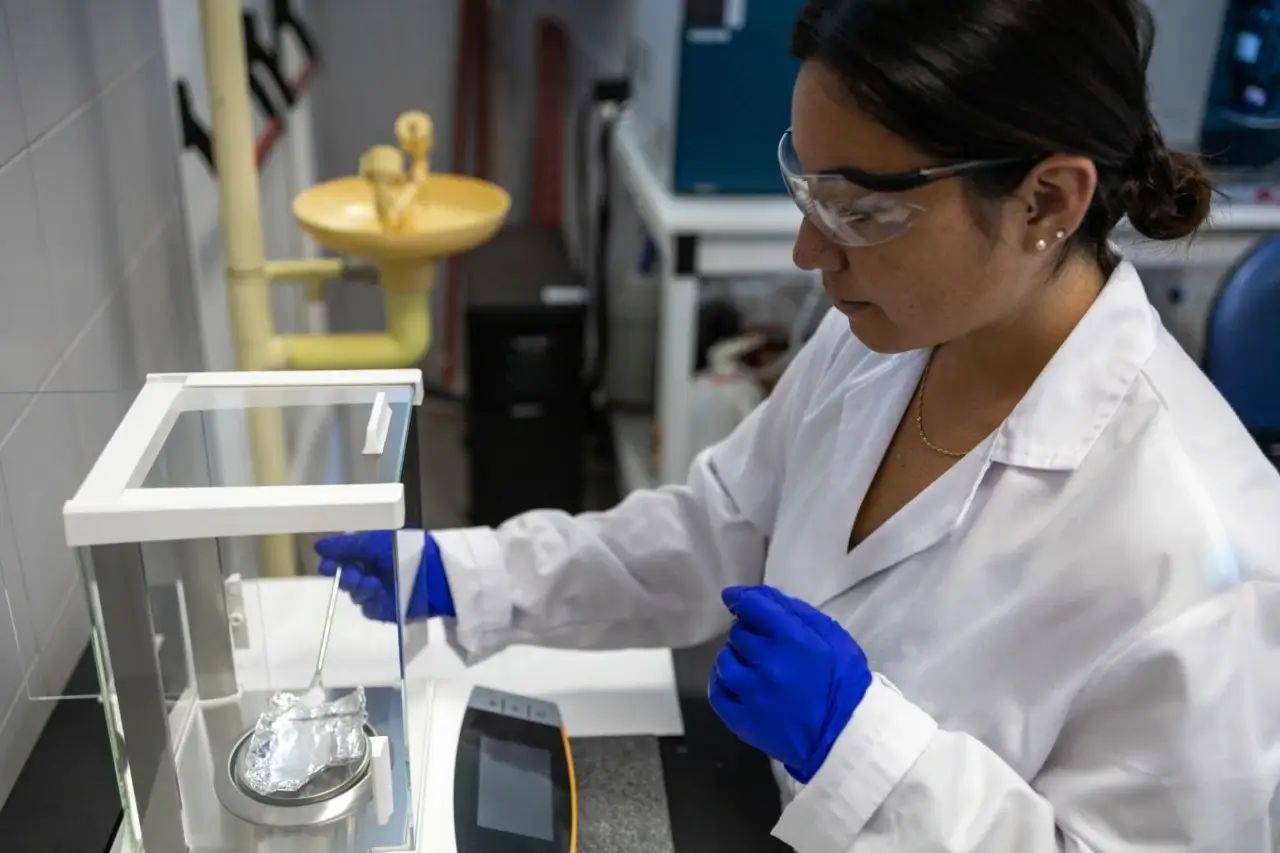

An Analytical Balance measures very small masses with high accuracy, typically to 0.0001 g (0.1 mg). Because even minor air movement can affect readings, these balances are equipped with a protective draft shield.

- Analytical Balance: Reads to four decimal places (0.0001 g). Commonly used in laboratories and research settings.

- Precision Balance (Top-Loading Balance): Reads to two or three decimal places (0.01 g or 0.001 g), with higher capacity and slightly lower sensitivity.

- Microbalance: Measures up to six decimal places (0.000001 g), ideal for extremely small samples or trace analysis.

1.2 Core Performance Indicators

When comparing models, focus on the following specifications:

- Readability (Graduation Value): The smallest increment the balance can display. For analytical applications, choose 0.1 mg or 0.01 mg readability for optimal precision.

- Maximum Capacity: The total weight the balance can measure accurately, including containers. Always select a model with enough capacity for your largest samples.

- Repeatability: Indicates how consistent results are when weighing the same sample repeatedly. Higher repeatability means greater reliability.

- Minimum Sample Weight: A key but often ignored factor. According to USP Chapter 41, weighing below this value produces excessive relative error. Always confirm this specification before purchase.

II. Selection Guide: Matching the Balance to Your Needs

Finding the right analytical balance means matching its capabilities to your workflow and environment.

2.1 Defining Application Requirements

Different applications demand different performance levels. The table below summarizes common use cases and recommendations:

| Application/Requirement | Recommended Specification |

| High Precision Research | 0.01 mg (Semi-Micro) Readability, Advanced Calibration |

| Routine QC or General Analysis | 0.1 mg Readability, Internal Calibration |

| Pharmaceutical or Regulated Industry | GLP/GMP Compliance, Data Traceability, IQ/OQ/PQ Support |

| Volatile or Toxic Samples | Large Chamber, Automatic Smart-Door |

| Airlock/Glovebox Integration | Compact Design, Interface Compatibility |

2.2 Managing Environmental Factors

Environmental disturbances are one of the biggest challenges in maintaining balance accuracy.

- Vibration and Airflow: Nearby machinery or open spaces can affect readings. Choose a balance with solid construction, advanced wind shielding, and vibration resistance.

- Temperature and Humidity: Fluctuations can alter readings. Many modern models include automatic temperature compensation to minimize drift.

- Static Electricity: In dry environments, static can cause samples to stick or jump. Consider using a built-in or external ionizer (static eliminator) for stable results.

2.3 Calibration Options

Calibration ensures long-term accuracy. Two systems are common:

- Internal Calibration (AutoCal):

The balance uses internal reference weights to adjust itself automatically.- Pros: Convenient, automatic, and less prone to user error.

- Cons: Slightly higher cost.

- External Calibration:

Requires placing certified external weights on the pan manually.- Pros: Lower cost, full control.

- Cons: Slower and more dependent on user skill.

III. Functionality: Efficiency and Data Management

Modern analytical balances combine precision weighing with smart data handling, connectivity, and user-friendly operation.

3.1 Data and Connectivity

Data traceability is essential for both workflow efficiency and compliance.

- Interfaces: Choose a model that supports RS-232, USB, or Ethernet/Wi-Fi depending on your setup.

- Traceability:: Ensure it records operator ID, time, date, and balance ID for audit trails and GLP/GMP compliance.

- Integration: Seamless connection with LIMS (Laboratory Information Management System) or ELN (Electronic Lab Notebook) prevents manual errors and improves productivity.

3.2 Operation and Ease of Use

Well-designed analytical balances simplify everyday weighing tasks.

- Touchscreen Display: A clear, intuitive interface reduces training time and minimizes operator mistakes.

- Built-in Applications: Programs for density determination, formula weighing, or statistical analysis save time.

- Automation Features: Functions like auto-opening doors speed up workflows and reduce sample handling errors.

IV. Decision Factors: Brand, Budget, and Support

A balance should deliver dependable performance for years, so it’s important to evaluate brands and long-term support.

4.1 Major Brands and Market Insights

The analytical balance market features a few well-established brands with distinct strengths:

- Mettler-Toledo: Renowned for innovation, excellent data management, and MinWeigh technology—ideal for research and regulated sectors.

- Sartorius: A German manufacturer known for reliability, ergonomic design, and intuitive controls.

- Stuccler: Offers affordable and stable models suitable for educational and general laboratory use.

| Accuracy Level | Typical Budget Range | Ideal Use |

| 0.01 mg (Semi-Micro) | High-End | Advanced Research, Method Development |

| 0.1 mg (Analytical) | Mid-Range | Routine QC, Pharmaceutical Testing |

| 1 mg (Precision) | Entry-Level | Basic Weighing, Sample Preparation |

4.2 Service, Validation, and Maintenance

The value of an analytical balance extends beyond its purchase price.

- Warranty and Repair: Choose suppliers with reliable after-sales service and local parts availability.

- Certification and Validation: For regulated industries, ensure IQ/OQ/PQ qualification services are provided.

- Maintenance: Plan for regular calibration and maintenance costs to preserve long-term accuracy.

Summary and Purchase Checklist

Selecting an analytical balance is about achieving consistent accuracy, efficiency, and compliance. A well-chosen instrument saves time, reduces errors, and ensures reliable data integrity.

Three Core Principles:

- Accuracy: Choose suitable readability and minimum sample weight.

- Environment: Protect from vibration, air, and static interference.

- Compliance: Ensure traceable data and qualified service support.

Quick Checklist Before Purchase:

| Category | Item | Notes |

| Accuracy | Readability (0.1 mg or 0.01 mg) confirmed? | |

| Minimum sample weight verified? | ||

| Maximum weighing capacity suitable? | ||

| Functionality | Calibration type (Internal/External)? | |

| Connectivity options available (USB, Ethernet, Wi-Fi)? | ||

| Required applications (density, formula, statistics)? | ||

| Environment | Anti-vibration and static protection needed? | |

| Service/Cost | Brand and budget range confirmed? | |

| IIQ/OQ/PQ qualification required? | ||

| Warranty and local service verified? |