Selecting the right laboratory balance is critical for ensuring the accuracy and reliability of your work. With numerous options available, deciding between a top-loading balance and an analytical balance can be challenging. This guide clarifies the key differences to help you choose the best tool for your specific needs.

Understanding the Two Main Types of Balances

What is a Top-Loading Balance?

A top-loading balance, often called a precision balance, is designed for weighing tasks that don’t require extreme accuracy. It’s a versatile, user-friendly tool suitable for a variety of lab environments.

- Key Features:

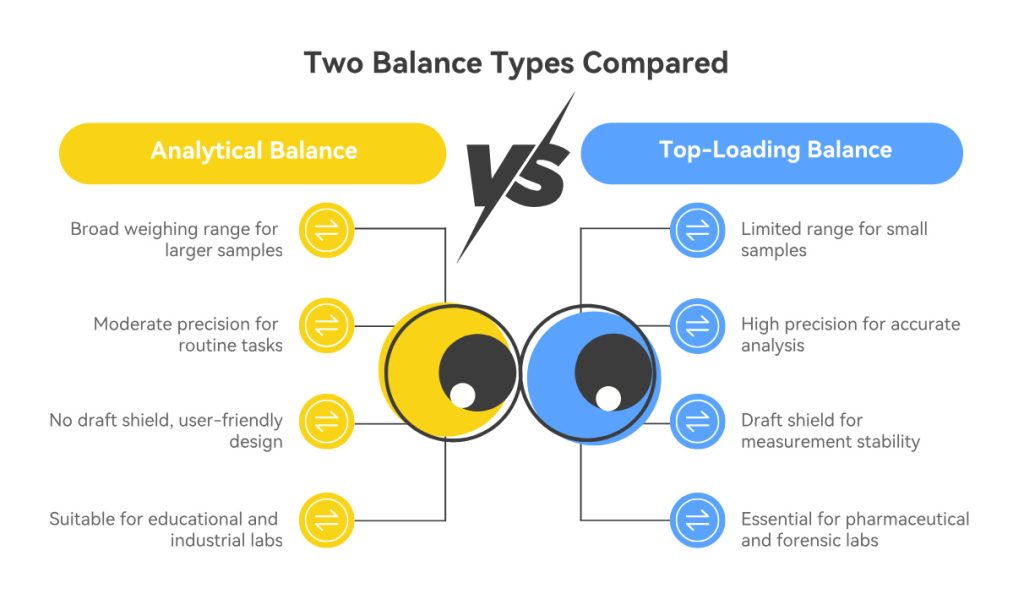

- Broad Weighing Range: Handles masses from a few grams to several kilograms, making it ideal for larger samples.

- Moderate Precision: Offers readability of 0.1g, 0.01g, or 0.001g, sufficient for many routine tasks.

- No Draft Shield: Lacks a glass enclosure, as it’s less sensitive to minor air currents.

- Applications:

- Routine Preparations: Weighing reagents for standard solutions.

- Rough Weighing: Quick, approximate measurements of chemical substances.

- Bulk Materials: Measuring large quantities in industrial settings.

- Educational Labs: Perfect for university or high school labs where high precision isn’t critical.

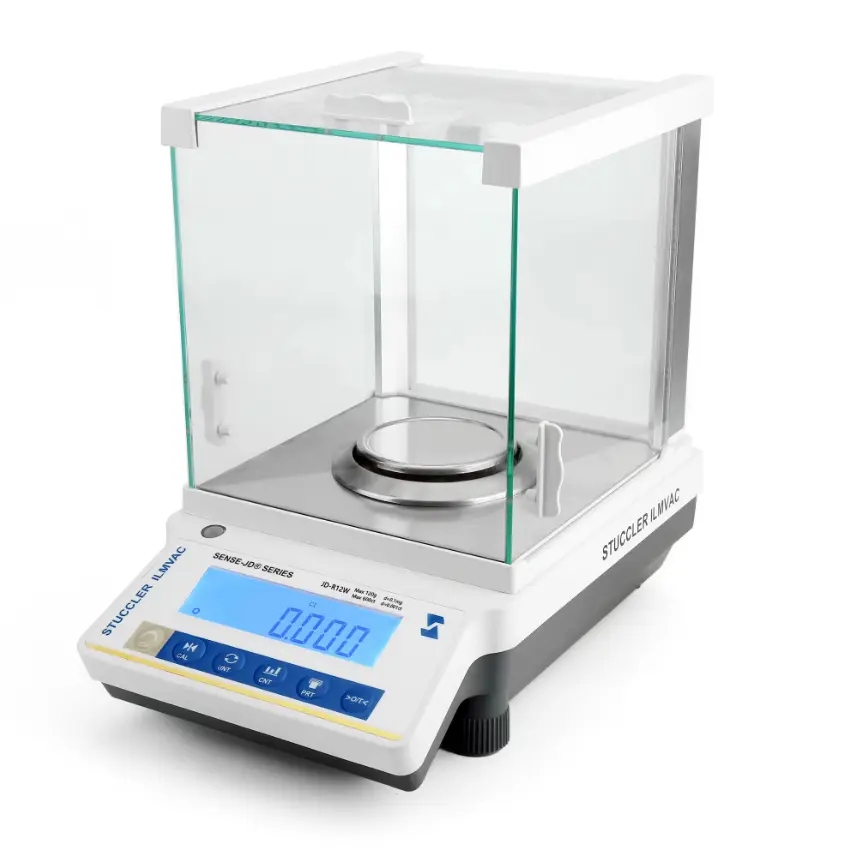

What is an Analytical Balance?

An analytical balance is a highly sensitive instrument built for precise quantitative chemical analysis. It’s designed to measure small masses with exceptional accuracy.

- Key Features:

- High Precision: Offers readability of 0.1mg (0.0001g) or better, ensuring pinpoint accuracy.

- Limited Weighing Range: Typically caps at around 300g, focusing on smaller samples.

- Draft Shield: Features a transparent enclosure to protect against air currents, ensuring stable measurements.

- Applications:

- Precision Analysis: Essential for gravimetric analysis in analytical chemistry.

- Pharmaceutical Formulation: Accurately weighing active pharmaceutical ingredients (APIs).

- Trace Substance Weighing: Measuring minute quantities in forensic or environmental labs.

- Quality Control: Verifying exact weights in manufacturing to meet strict standards.

Core Differences: Top-Loading vs. Analytical Balances

To make the comparison clearer, here’s a breakdown of the key differences between top-loading balances and analytical balances.

| Feature | Top-Loading Balance | Analytical Balance |

| Readability | 0.1g, 0.01g, or 0.001g | 0.1mg (0.0001g) or better |

| Weighing Capacity | Wide (grams to kilograms) | Limited (up to ~300g) |

| Draft Shield | No | Yes (essential for stability) |

| Weighing Speed | Fast | Slower (requires stabilization ) |

| Calibration | Less frequent, depending on use | Frequent, critical for accuracy |

| Price | More affordable | Higher cost |

| Operating Requirements | Tolerates minor vibrations and drafts | Sensitive to vibrations, drafts, and temperature changes |

| Application Environment | General lab, industrial, and educational settings | Controlled environments (e.g., dedicated balance rooms) |

How to Choose: Matching the Balance to Your Needs

Your choice between a top-loading balance and an analytical balance depends on your lab’s specific requirements. Here are some scenarios to guide your decision.

Scenario 1: Daily Solution Preparation

Need: You’re weighing several hundred grams of a solid for a solution, with an accuracy requirement of 0.1g, and speed is a priority.

Recommendation: A top-loading balance is ideal. It provides the capacity and speed you need without the expense or sensitivity of an analytical balance.

Scenario 2: High-Precision Research

Need: Your work involves measuring trace substances, requiring accuracy to the milligram level or better.

Recommendation: An analytical balance is essential. Its superior precision ensures reliable, reproducible results critical for research.

Scenario 3: University Teaching Lab

Need: You’re equipping a lab for students to practice basic weighing techniques, where ultra-high precision isn’t necessary.

Recommendation: A top-loading balance is cost-effective and durable, making it perfect for student use in educational settings.

Scenario 4: Quality Control in a Manufacturing Environment

Need: You’re verifying product weights in a pharmaceutical or quality inspection facility, requiring high precision and repeatability.

Recommendation: An analytical balance is the go-to choice. Its accuracy and consistency are vital for meeting stringent quality standards.

Purchasing and Usage Tips: Getting It Right

- Prioritize Performance Over Price: Don’t choose based solely on cost. Focus on key specifications like readability, repeatability (consistent results for the same mass under identical conditions), and linearity (accurate weight readings across the balance’s range).

- Optimize Your Environment: Place balances on a stable, level surface, away from vibrations, drafts, and direct sunlight to ensure accurate measurements.

- Correct Operation: Allow the balance to warm up before use, use appropriate weighing containers, and always tare (zero) the balance before adding your sample.

- Calibrate Regularly: Calibration is critical for accuracy. Whether using internal or external calibration, schedule it based on your balance’s usage and manufacturer guidelines.

- Choose a Reputable Brand: Opt for trusted manufacturers like Stuccler, known for quality and reliable customer support. Strong after-sales service is invaluable for maintenance and troubleshooting.

Summary: Let Your Lab’s Needs Guide Your Choice

The decision between a top-loading balance and an analytical balance hinges on your lab’s priorities. For tasks requiring speed and higher capacity without extreme precision, a top-loading balance is a reliable, cost-effective workhorse. For research or quality control demanding the highest accuracy, an analytical balance is indispensable for ensuring data integrity and compliance.

What type of weighing tasks does your lab handle most often? What factors matter most when selecting a balance? Share your thoughts and experiences in the comments below!