The choice of an electronic balance today is driven by data integrity and verifiable precision, not just raw specifications. New regulations and evolving technology demand a focused approach to actual measurement accuracy.

Here are the critical areas for selection:

I. Defining Your Application Needs and Balance Type

Selecting the correct electronic weighing instrument begins with clearly defining your application and its required level of precision. The table below outlines the primary balance categories and their typical uses.

| Balance Type | Readability (d) Typical Range | Maximum Weighing Capacity (Capacity) Typical Range | Core Application Scenarios |

| Micro/Ultra-Micro Balances | 0.0001 mg – 0.001 mg | 2 g – 10 g | Drug development, filter weighing, high-precision analysis. |

| Analytical Balance | 0.01 mg – 0.1 mg | 100 g – 320 g | QA/QC laboratories for chemical analysis and standard preparation. |

| Precision Balance | 1 mg – 100 mg | 300 g – 30 kg | Ingredient preparation, density measurement, large sample weighing, and teaching. |

| Platform Scale/Industrial Scale | 0.1 g – 10 g | 30 kg – 600 kg+ | Industrial environments for weighing large quantities of materials and for inventory management. |

II. Key Points for Selecting Your Electronic Balance

Choosing a laboratory balance involves evaluating several interconnected technical parameters. We break down the most critical factors that determine the true performance and compliance of any weighing equipment.

1. Readability (d)

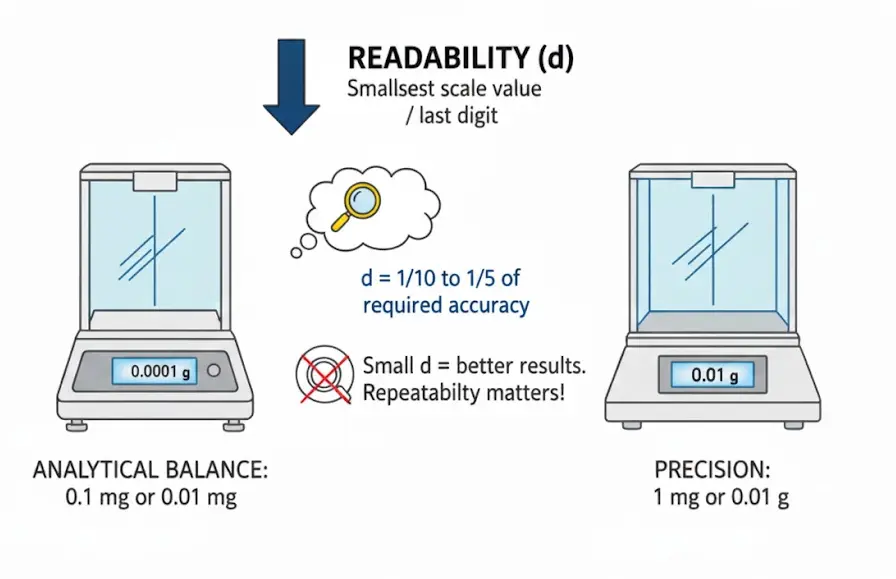

The smallest scale value displayed by the balance, often referred to as the resolution or the last digit.

Selection Principle:

- Don’t overemphasize readability: Ensure the readability is only 1/10 to 1/5 of your required accuracy. Why? Because the actual, reliable accuracy is determined by the balance’s repeatability. A smaller d doesn’t guarantee better results.

- Matching Requirements: Analytical balances typically require 0.1 mg or 0.01 mg, while precision balances often require 1 mg or 0.01 g for routine tasks.

2. Repeatability (Standard Deviation SD)

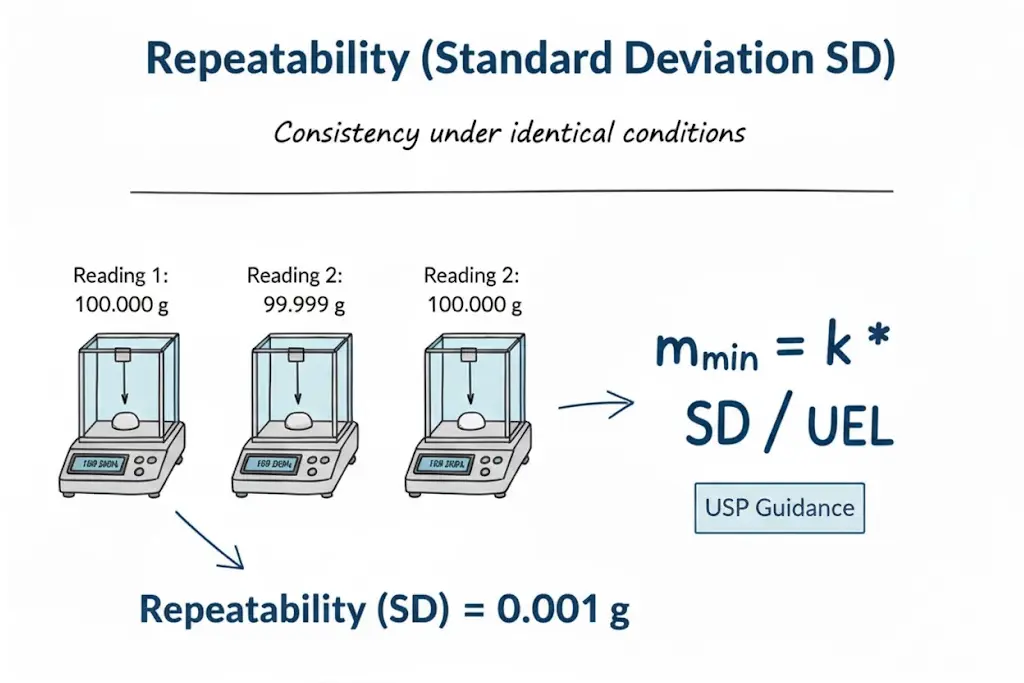

Repeatability is the consistency (expressed as standard deviation SD) between readings when weighing the same object multiple times under identical conditions.

Selection Principles (Most Important):

- Superior to Readability: Repeatability is the gold standard for measuring the actual accuracy of any scientific balance. A high-readability weighing balance with poor repeatability is unreliable.

- Focus on mₘᵢₙ : Repeatability is the key parameter for calculating the crucial minimum weighing value (mₘᵢₙ ), as mandated by USP and other regulatory bodies. Always obtain the SD data from the supplier.

3. Linearity/Accuracy

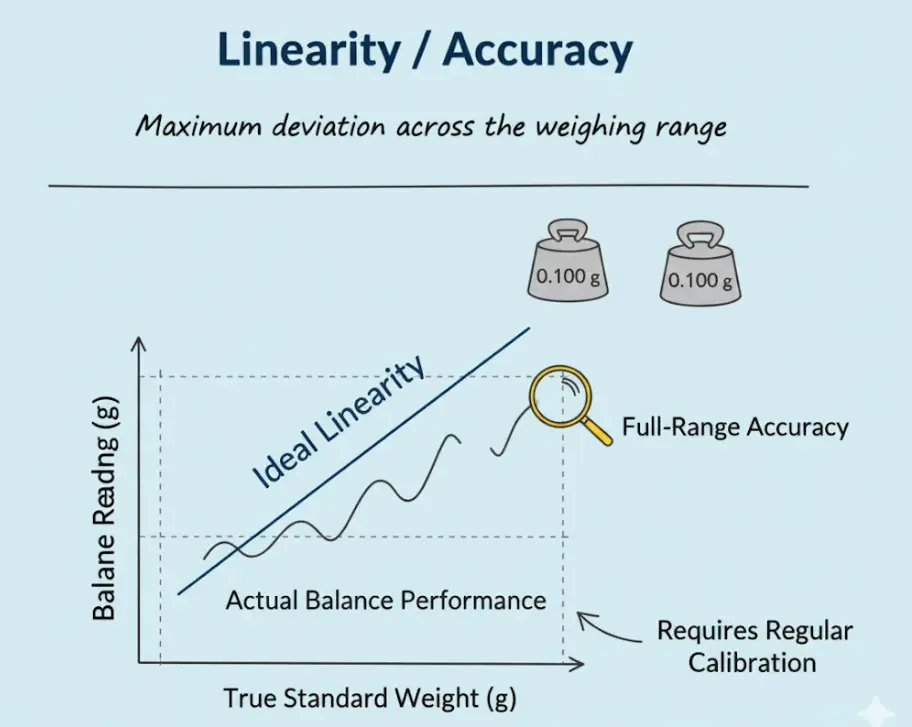

This measures the maximum deviation between the balance reading and the true standard weight across the entire weighing range.

Selection Principles:

- Full-Range Accuracy: Ensure the precise balance remains accurate near both the maximum capacity and the minimum sample size.

- Importance of Calibration: Good linearity requires regular and accurate calibration to maintain performance over time. This is critical for applications demanding high accuracy across the full range.

4. Stability

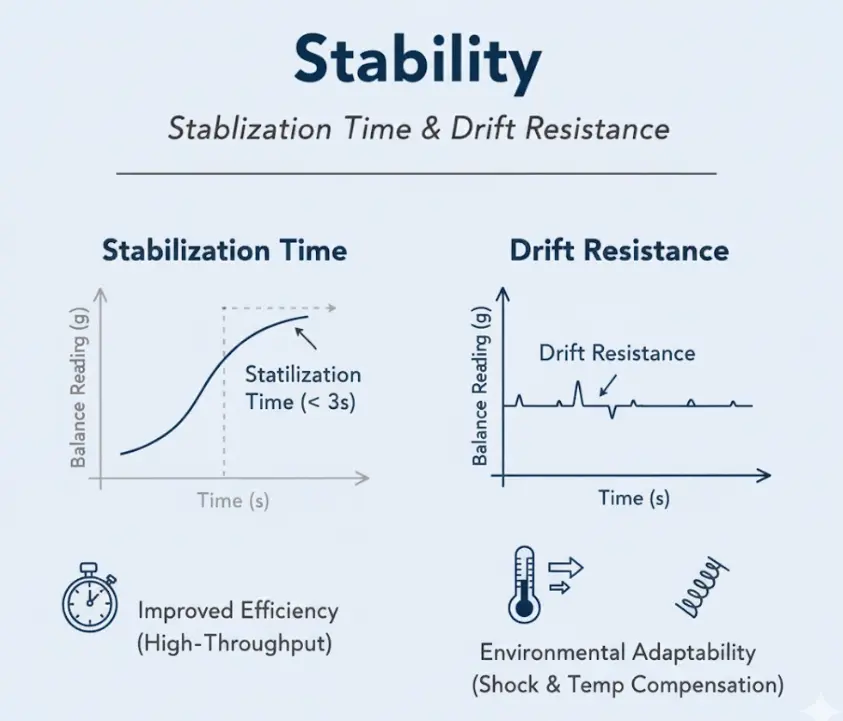

Stability is the time required for the balance to reach its final reading after loading (stabilization time), and its ability to maintain the reading consistently over a period of time (drift resistance).

Selection Principles:

- Improved Efficiency: For high-throughput applications (like QC sampling), shorter stabilization times are essential (ideally less than 3 seconds).

- Environmental Adaptability: Check if the weighing instrument has built-in shock resistance and temperature drift compensation technology, which is vital for maintaining stability in challenging environments.

5. Calibration System

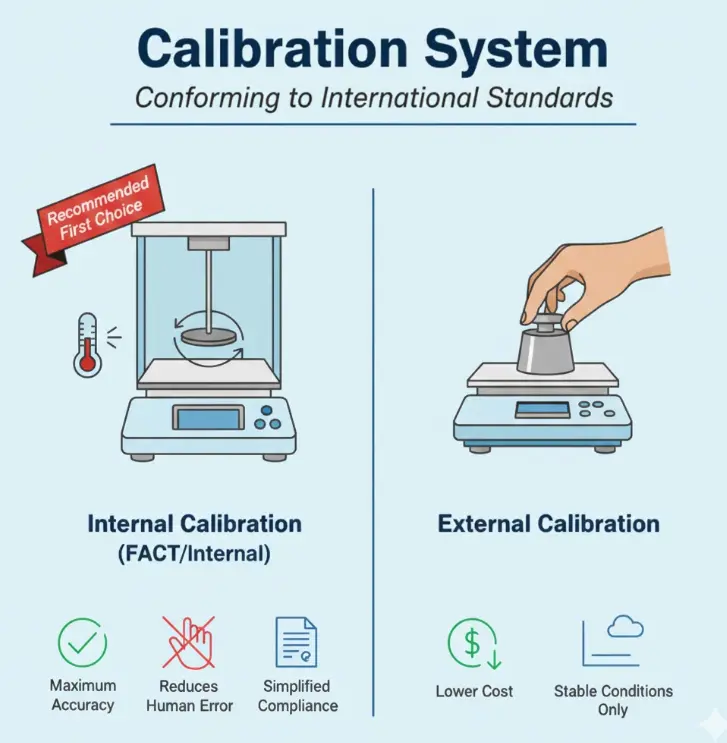

The process of ensuring the digital balance reading conforms to international standards.

Selection Principles:

- Internal Calibration (FACT/Internal): Recommended as the first choice. The lab balance automatically senses temperature changes and adjusts accordingly. This ensures maximum accuracy, reduces human error, and simplifies compliance record-keeping.

- External Calibration: This option is lower cost but requires manual operation using standard weights. It is suitable only for environments with low precision requirements and stable conditions.

6. Data Connectivity & Smart Features

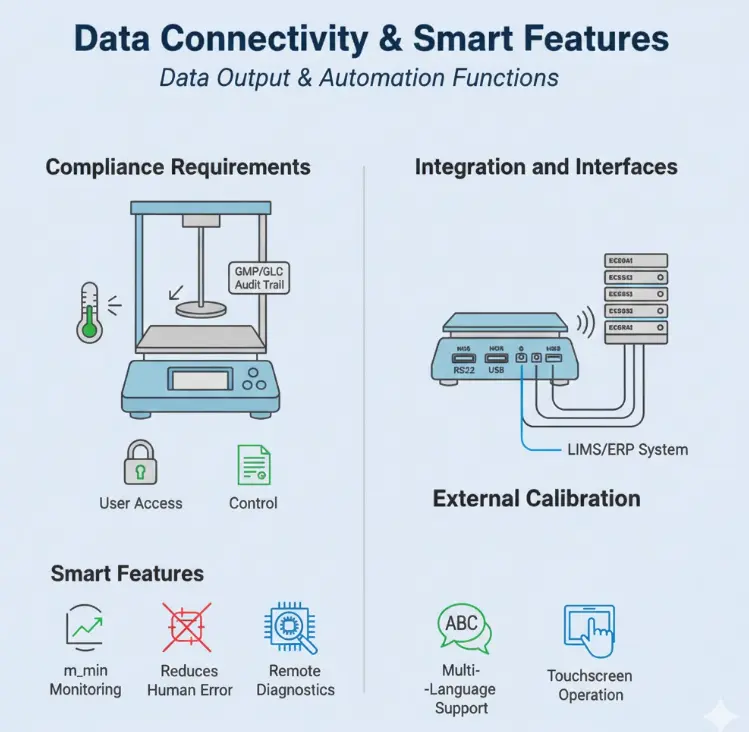

The data output capabilities and built-in automation functions of the precision weighing tool.

Selection Principles:

- Compliance Requirements: To meet regulatory requirements such as GMP/GLP and FDA 21 CFR Part 11, the balance must have robust audit trail and user access control functions.

- Integration and Interfaces: Determine the required interfaces (RS232, USB, Ethernet, Wi-Fi) for seamless data transmission and integration with LIMS or ERP systems.

- Smart Features: Consider efficiency improvements from features like automatic minimum weighing value monitoring, remote diagnostics, multi-language support, and intuitive touchscreen operation.

7. Operating Environment Considerations

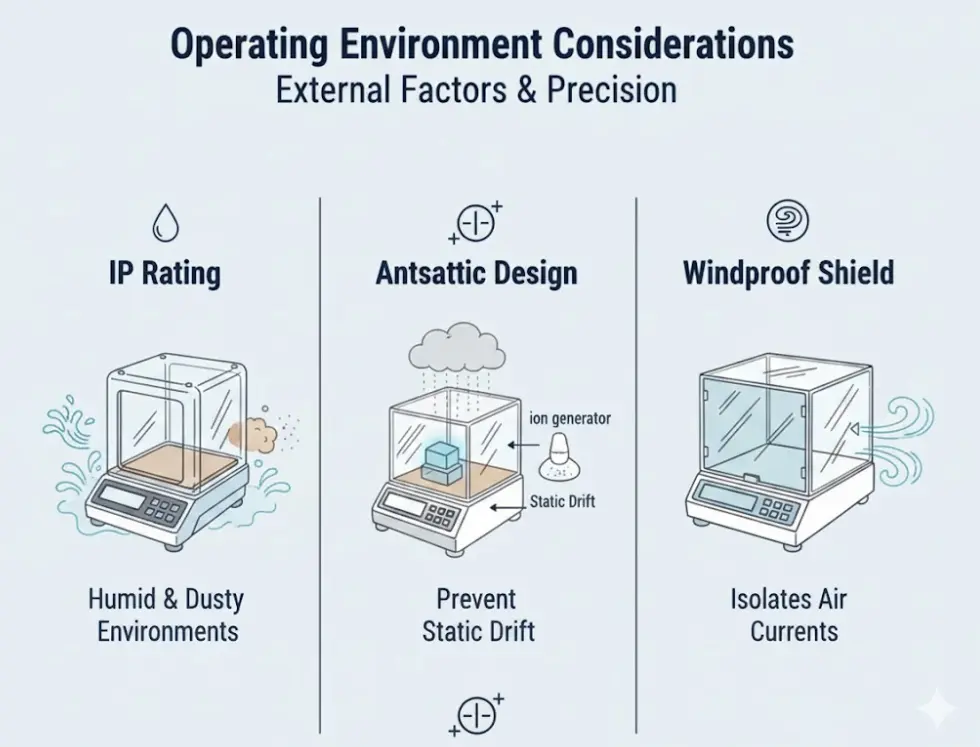

The impact of external environmental factors (temperature, humidity, vibration, dust) on the precision instrument’s performance.

Selection Principles:

- IP Rating: For use in humid, dusty, or potentially chemical-contaminated industrial/food processing environments, the IP rating is a critical durability indicator for your digital weighing scale.

- Antistatic Design: For weighing minute powders or samples, a built-in ion generator or special antistatic coating is required to effectively prevent drift caused by static electricity.

- Windproof Shield: All analytical balances must be equipped with an effective windproof shield design to isolate the weighing process from air currents.

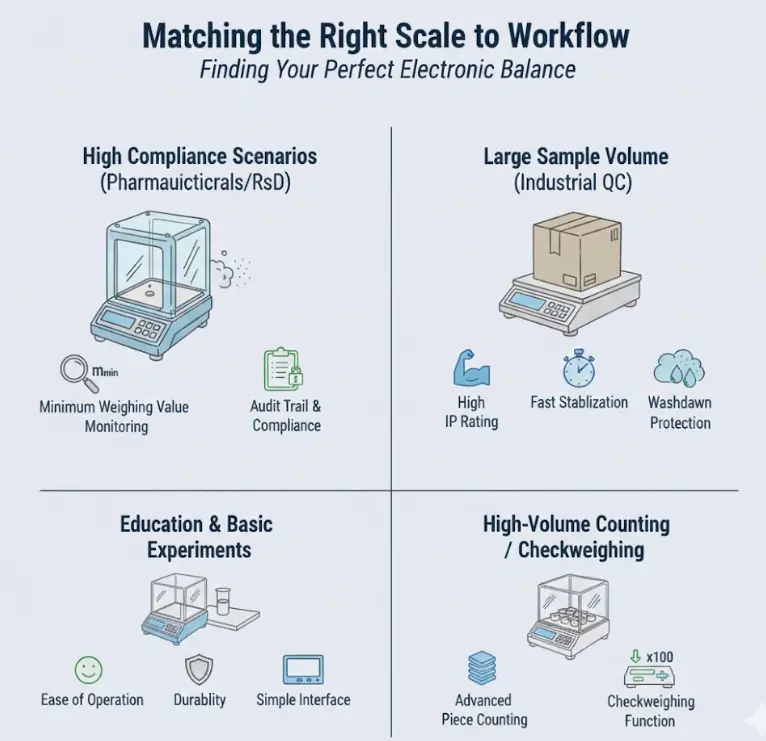

III. Application Scenarios and Recommendations

Matching the right electronic scale to your specific workflow is the final step in a successful purchase.

- High Compliance Scenarios (Pharmaceuticals/R&D): Focus on Analytical Balances with ≤0.1 mg readability or Micro Balances. Crucially, they must feature minimum weighing value monitoring and robust audit trail capabilities to meet strict regulatory demands.

- Large Sample Volume Scenarios (Ingredient Preparation/Industrial QC): Focus on robust Precision Balances or Industrial Platform Scales. Key features are high maximum weighing capacity, fast stabilization speed, and high IP rating (for washdown/protection).

- Education and Basic Experiments: Focus on cost-effective Basic Precision Balances. Key requirements are ease of operation, durability, and a simple interface. Data compliance requirements are typically lower here.

- High-Volume Counting/Checkweighing: Choose Precision Balances with built-in advanced Piece Counting or Checkweighing functions, optimizing throughput and inventory accuracy.

Conclusion

The 2025 guide to selecting a high-performance electronic balance hinges on moving beyond simple specifications. Prioritize repeatability, ensure your chosen model guarantees the correct minimum weighing value (mₘᵢₙ ) for your sample size, and verify its capabilities for data compliance.

To find the perfect electronic balance that seamlessly integrates the latest technology with uncompromising reliability, we invite you to explore the extensive range of electronic balance products available at Stuccler. We offer expert guidance to ensure your next investment meets all your precision, efficiency, and regulatory needs.